Ultrasonic cleaning may sound like a complicated or even scientific method of cleaning, but once you understand its process, it’s actually quite simple. Ultrasonic cleaning is a fast and efficient cleaning method that uses ultrasound energy and with the help of additional cleaning concentrates with a process called cavitation penetrates deep into the pores of any object.

Today, ultrasonic facial cleansing is one of the most popular and effective treatments used by women all over the world. In addition, we can use ultrasound to clean jewelry, as well as many machines that cannot be thoroughly cleaned in any other way. Ultrasonic machines are modern electrical devices intended for ultrasonic washing – ultrasonic cleaning of objects made of different materials (metal, plastic, glass, etc.). Cleaning devices that use ultrasound can be of different dimensions, from small drawers in dental offices to large industrial plants. Ultrasound is often used to clean laboratory dishes.

If we were to compare classic cleaning with ultrasonic cleaning, we would see that the difference is very visible. Traditional manual cleaning removes only 60%-70% of dirt, grease, and stains, while ultrasound can almost completely remove stains – up to 98%. Industrial cleaning is among the biggest challenges today. Cleaning industrial tools and parts may not be the first association when you think of industry and manufacturing. In the industry, it is sometimes even more difficult to reach all the hidden places. Tools and equipment used in industry, manufacturing, and restoration can be very hard and sometimes very dangerous to clean. In addition, especially in industry, we often have a very large number of things to clean. If you clean a large number of elements one by one, it can take a very long time.

Source: finishingandcoating.com

Contents

A more effective effect

Ultrasonic activity is a perfect solution for the problems when plain water can do nothing. The cleaning solution contains ingredients designed to make ultrasonic cleaning more effective. For example, a decrease in surface tension increases the level of cavitation, so the solution contains a good wetting agent (surfactant). Cleaning with an ultrasonic cleaner has become an ideal and affordable alternative to laborious “manual” cleaning with often heavy solvents. The ultrasonic cleaning technique is not only reserved for professionals. Experience shows that buying an ultrasonic cleaner pays off quickly in practice. Aqueous cleaning solutions contain detergents, wetting agents, and other components and have a major impact on the cleaning process. The correct composition of the solution depends on the cleaned object.

Usage

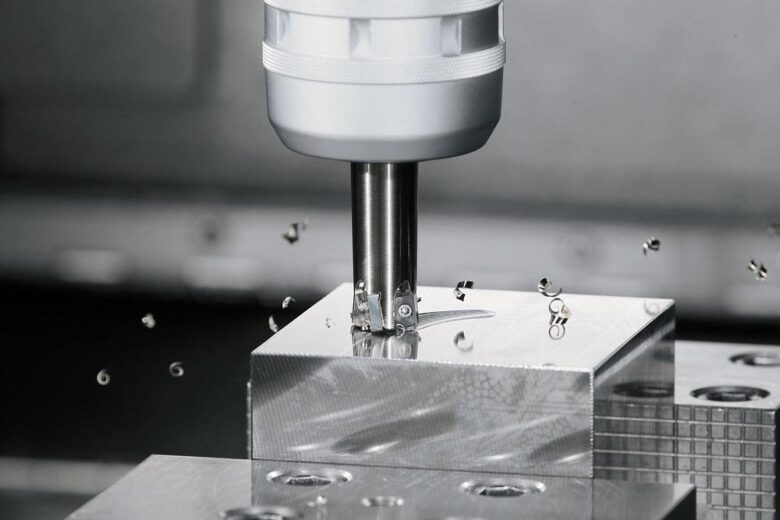

Ultrasonic removal of materials is used in processing: milling, drilling, grinding, threading, engraving in molds, cutting, cutting, etc. The materials for processing are characterized by high hardness and brittleness, so they are most often hard metal, glass, ceramics, plastic, etc. The removal of material from the workpiece takes place fact that abrasive grains of high hardness, which are in the liquid fluid, enter the working space between the vibrating tool and the front side of the workpiece, causing its erosion.

Source: canadianmetalworking.com

Low cost

Ultrasound has many advantages, from the creation of an ultrasound image in real-time, the mobility of ultrasound devices, to the relatively low cost compared to other devices. We can conclude that the appearance and study of ultrasound have brought great changes in all areas of science and technology and that with further development an application will be even greater.

The importance of the choice of liquid

The number of technological operations using ultrasound is increasing. In addition to the parameters (power, frequency, amplitude), the type of material of the workpiece and the tool have an influence on the quality of the workpiece when applying ultrasound in the process of material removal (dimensional processing). It is also important to choose the type of working fluid, as well as the size and type of abrasive grains.

Detailed cleaning

If we think about the advantages of ultrasonic cleaning, we will say that it is without a doubt the most detailed cleaning that provides immediately visible results because the liquid goes to the deepest pores in objects, that is, to places where no brush or cloth can reach.

Due to the listed advantages, ultrasonic cleaning is one of the most effective, easiest, most economical, fastest, most productive, and highest quality methods of cleaning – washing. Until recently, there was also a misconception that ultrasonic baths are extremely expensive devices, but now you can make sure that the prices of these devices are extremely favorable and affordable. You can find more if you visit ultratecno.

There are many other facts that favor this method of cleaning. Environmental protection is certainly one of them because ultrasonic cleaning effectively reduces pollution. In addition, it is easy to handle and reduces manpower, as well as the working time, which is a quarter shorter than the time of manual cleaning.

Source: ultratecno.eu

Maintenance

Cleaning machine maintenance is very simple and undemanding. Proper maintenance of ventilation equipment is necessary, as well as regular testing of the insulation performance of ultrasonic cleaning machines. Before each subsequent use, check the power supply to protect the machine from burning out due to inadequate power supply. Then when you notice that it is time to change the cleaning fluid, do it so that deposits do not form on the inside of the machine, which is very difficult to remove.

An ultrasonic bath is used for washing smaller parts. An ultrasonic bathtub is an economical and ecological device for washing and cleaning vehicle parts. A liquid through which ultrasonic waves propagate is used for washing. A solution of water and a suitable degreaser is used for washing parts. Ordinary or demineralized water can be used, which is more efficient in the washing process.

Final thoughts

The number of technological operations using ultrasound is increasing. In addition to the parameters (power, frequency, amplitude), the type of material of the workpiece and the tool have an influence on the quality of the workpiece when using ultrasound in the material removal process. It is also important to choose the type of working fluid, as well as the size and type of abrasive grains. Narrow and deep openings can be formed by dimensional shaping.