Ever wondered what lifting solutions are available for the construction industry? This article looks at five genius lifting solutions that could transform the way your workforce operates. These solutions are all capable of increasing efficiencies whilst helping to reduce injury from the manual handling of large, heavy construction materials.

Contents

1. Mini Cranes

Source: UNIC Cranes Europe

We all know that cranes are vital during the construction of large buildings. You only need to look across a developing city to see how popular they are during the construction of office blocks and other high-rise buildings. Most of these cranes are fixed structures, built in modules to the requirements of a specific project. Others are large, mobile cranes that can drop by a site for short term work or a one-off lifting job. But what happens when you need something smaller? Do you have to pay for a large mobile crane?

Fortunately, a variety of mini cranes have burst onto the market in recent years. There a few different types to choose from including; spider cranes, pick and carry cranes, and even mini crawler cranes. All these lifting solutions are designed to be as compact as possible with good maneuverability. Spider cranes, for example, are designed so they can fit through most commercial doorways. This makes them ideal for interior lifting jobs which might otherwise have to be done via more traditional methods.

2. Glass Lifting Equipment

Source: Packline Materials Handling

Another genius lifting device for the construction industry is a glass lifter. Traditionally, large panes of glass had to be man-handled into position. This might have involved carrying the glass up stairwells, scaffolding, or even winching it into position. All these methods provide a hazardous working environment and have been responsible for serious injuries all over the world. According to CPS Lift, Glass lifting equipment helps to mitigate this risk and offer improved worker safety, together with faster installation times.

There several lifting solutions available for the glazing industry. Most of these rely on vacuum technology in the form of suction pads attached to some form of a crane or self-propelled machine. Whilst these solutions can be expensive, the benefits they offer far outweigh the price. Glazing robots are a relative newcomer to the industry and are dedicated glass lifters suitable for both indoor and outdoor use. They are often self-propelled with a remote operation which helps to improve visibility and reduce possible injury from falling objects.

3. Stone Lifters

Source: YouTube

A slightly less common solution for construction workers is the stone lifter. Also referred to as ‘stone magnets’, these devices can lift large stone blocks and border stones into position with minimal effort. Most feature a grabbing design that pinches the block at each side to lift it whereas others feature suction technology – much like a glass lifting robot.

Stone grabs are more suited to the lifting of large, heavy blocks. They often feature two rubber grips to avoid damage to the stone. Suction lifters are mostly designed for the positioning of commercial paving slabs, but some are suitable for heavier blocks and can lift as much as 1000kg.

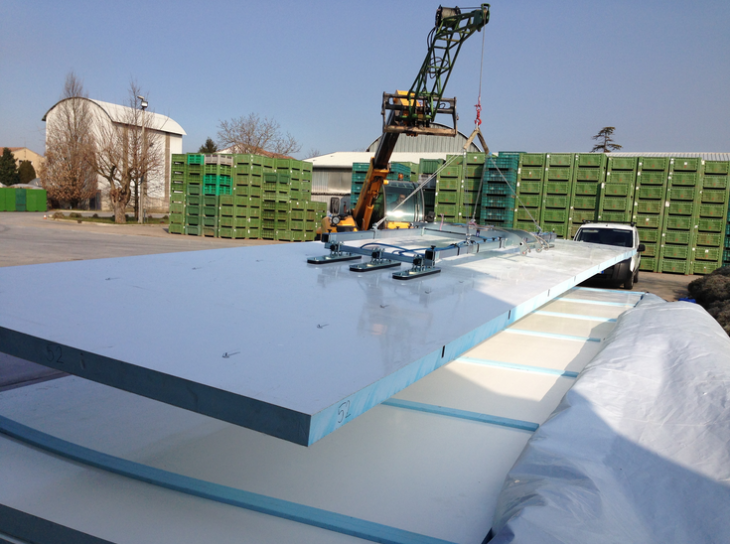

4. Cladding Lifters

Source: Vacuum Cladding Lifters

Cladded buildings not only look great, but they can also offer improved durability over traditional building materials. For this reason, many high-rise buildings and office blocks are now built with large panels of cladding. Traditionally, the cladding had to be craned into position with the help of straps and then man-handled into position ready for fixing. The drawback of this method is that installation is often slow and can lead to injury and falling objects.

Cladding lifters were invented to help speed up the installation of cladding and reduce the potential for falling objects. They work in a very similar way to vacuum based glass lifting equipment and do away with the need to manually strap cladding ready for lifting into position. Suction pads make light work of gripping the cladding which can then be lifted into position safely and securely. The cladding is then simply fixed into position before the suction is removed.

5. Access Platforms

Source: HS-RENTAL

When you think of access platforms, you might not think of them as a lifting solution. Most access platforms exist to allow workers to gain access to different heights, but did you know some are even able to act as cranes? Specific models of access platforms come with extras, allowing you to specify lifting hooks as part of the machine. This allows them to become dual use, helping to reduce the number of machines required on site.

Overview

Lifting solutions are vital for the construction industry. They can help to improve worker safety, speed up installation times, and make your company stand out as a fully equipped construction firm. Will your company invest in such solutions? Leave your comments below.