If you ask any manufacturer or designer out there, it’s possible that they’ll tell you that they don’t know exactly what is included in the cost of assembling a printed circuit board. After all, in most situations, they simply send their orders out of habit, without knowing that they aren’t optimized for saving costs.

This is why you might be wondering – how much does a high-quality PCB assembly cost? Well, simply said, it’ll depend on a lot of factors and those factors are exactly what we’ll discuss in this article today. Let’s take a closer look at all the things that are included in the assembly process, all of which will influence the last cost:

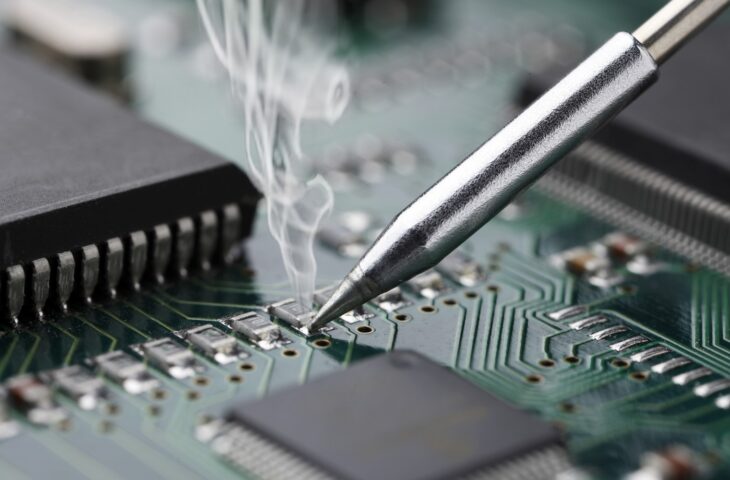

Source: verityems.com

Contents

1. The Layers + The Scope

Although this is something quite obvious, it’s still worth mentioning – the larger your board is and the more layers it has, it’ll be more costly to assemble it. You’ll want to ensure that your design can adapt to the board sizes properly as well. There are various material sizes that different organizations use, ranging from 14×18 to 24×30.

If you want to cut costs and minimize wasting the boards, you must ensure that you utilize the entire area. If you only utilize one part of the board, you’ll basically be throwing your money away. Additionally, a lot of layers will increase your expenses, however, this is something that you cannot save on, especially if your layout is complex.

2. The Materials of The Pieces And Boards

If you, for instance, require certain board properties such as fire resistance, thermal rating, or high TG, you should expect your final price to be more than you initially planned. However, you could choose to give the contractor a little bit of flexibility in order to reduce the final expenses you’ll have. How can you do this?

Well, simply tell your ECM that they should use some alternative brands for the materials, however, ones that have similar properties to the expensive materials they would use. This means that your ECM won’t have to purchase one component for the assembly, instead, they can purchase in bulk, which will cut their and your expenses.

Source: Hetech

3. What do You Need – Through-Hole or SMT?

SMT or as it’s also referred to surface mount tech is automated in most electronic production organizations. This will make the cost lower than the standard, at least when it comes to the labor costs. Through-hole, on the other hand, is still done by traditional hand assembly and it cannot be avoided since it might be needed for connections that are constantly under a lot of stress.

Now, depending on your needs, an SMT might be able to replace it, and keep in mind – the fewer through-hole processes are needed, the less it’ll cost in the end. If you want to read additional information on this topic, you can check out what the experts from pcbonline.com have to say.

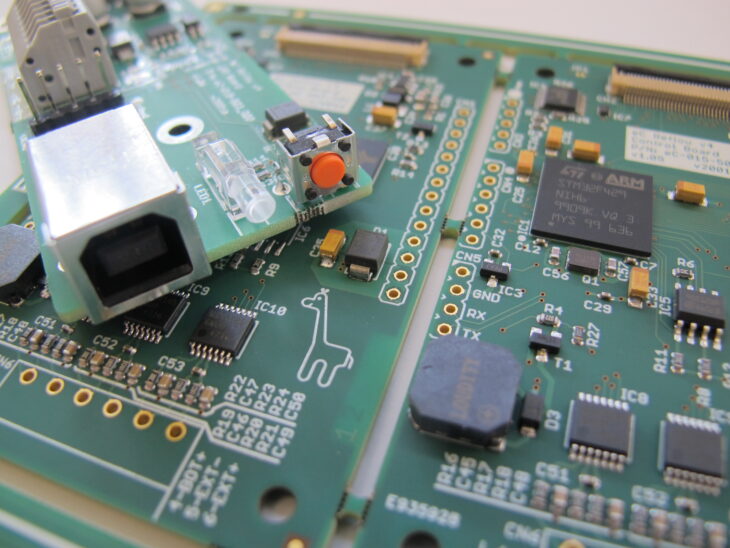

4. The Complexity of The Scheme

You should always strive to lower how complex your PCB layout and design are. After all, if the manufacturer needs to work extra hard to achieve what you have imagined, it’ll increase the expenses you’ll have. For instance, if you’re capable of designing the assembly so that the components are on one side of the board, you won’t need to pay twice for the surface mount process.

However, some designs do require complexity, and some of the features such as a BGA, require it to be inspected twice. Other features such as the coating you opt for will require an additional step in the assembly process. Although these features are somewhat necessary for certain products, they’ll increase the price, so, if possible, avoid them.

Source: Eurocircuits

5. Meeting The Industry Standards

You might not realize this yet, but certifications and standards must be looked at as investments that are long-term, as well as one that needs frequent maintenance. So, this is why, for example, organizations that manufacture IPC Class 3 electronic components for the aerospace industry need a lot of things from their contractors.

Since the projects are high-risk, the ECM will be responsible for a wide range of things, however, the most important ones are keeping track of all the lots, keeping records and documents for month, years, and sometimes even decades, and they must keep updated on all the regulations and standards of specific industries.

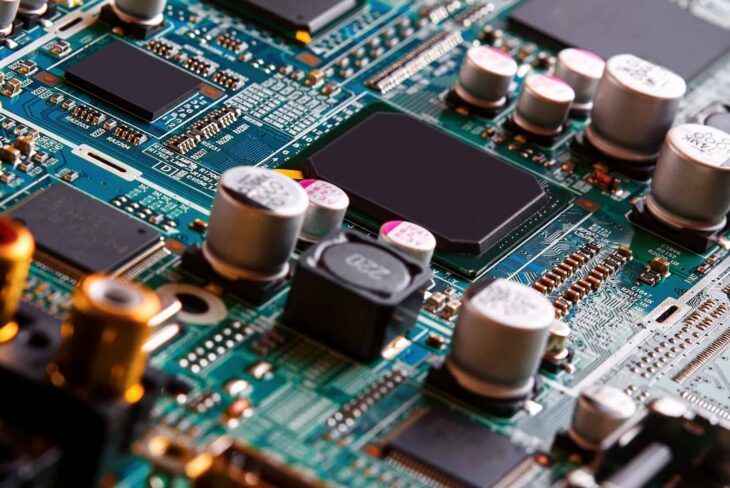

6. The Ordered Quantity + The Setup Time

If you choose to order a large quantity of PCBs, the organization you have ordered them from will probably give you a discount on your order. After all, they’ll need less time for setting everything up and there will be fewer things they’ll have to do. Hence, if you require 400 assemblies annually, you should place one order for all of them instead of ordering 40 ten times.

Source: American Products Inc.

7. Placing an Order on Time

If you require a lot of PCBs in a short time, the contractor will most likely charge you additionally. After all, the less time they have, the faster they’ll need to work, hence, it’s logical that they would charge more. This is why you should ensure that you always place your orders before you actually need the boards and by doing so, you’ll enable the manufacturer to find cheaper components, but more importantly, you’ll allow them to take their time with your order.

8. Additional Services Will Cost Extra

If you need additional services like assistance when designing, testing of the PCBs, prototyping, as well as other services, they’ll, of course, cost you extra. Hence, when you’re opting for a partner, consider whether or not they offer these services, as well as whether or not you’ll actually need them.

Source: Siemens PLM

Conclusion

There is a wide range of things that influence the overall cost of assembling PCB boards. However, there are some things that we mentioned above, all of which will help you reduce the expenses you’ll have, and no matter what you choose to do, ensure that you meet all the standards and regulations of your industry.

So, now that you have learned about all the things that go into the price of assembling printed circuit boards, you might not want to lose any more time. Instead, you should start searching for an organization that will help you manufacture and assemble the PCB your company needs.