Whether you are an electronics enthusiast working on a DIY project, an engineer designing a cutting-edge piece of hardware, or a technician looking to enhance existing machinery, a current sensor can make or break your endeavor.

This current transducer is an indispensable device that converts electrical currents into measurable signals, enabling effective monitoring and control. Making a well-informed decision in this regard can be the key to the success of your project, saving you precious time and resources that might otherwise be spent on troubleshooting.

In this extensive article, we will delve into the intricate process of selecting the ideal current transducer for your specific project needs.

Source: instrumentation2000.com

Contents

Understanding Your Application

To embark on the journey of selecting the perfect current transducer, you must first gain a profound understanding of your application. This involves taking into consideration various critical factors:

- AC vs. DC: Determine whether your project involves alternating current (AC) or direct current (DC). While some transducers are versatile enough to handle both types, it is paramount to identify your precise requirement at this stage.

- Transient Conditions: Assess whether your application entails rapidly changing currents, commonly referred to as transient conditions. If this is the case, selecting a transducer with a fast response time becomes imperative to ensure accurate monitoring.

- Environmental Considerations: The environment in which your transducer will operate is a pivotal consideration. Will it be situated indoors, outdoors, or in a potentially hostile environment exposed to chemicals or extreme temperatures? This knowledge will inform your choice of a transducer with the necessary ruggedness and durability.

Determining the Measurement Range

Every project comes with its unique current range requirements. It is imperative to choose a current transducer that not only has the capacity to handle the maximum current expected but also delivers precise readings for the average operating current.

For instance, if your project’s maximum current is 50A but typically operates around 10A, opting for a transducer rated for a 0-10A range may prove insufficient, while a 0-100A transducer might be excessive. The optimal choice may be a 0-60A transducer that strikes the perfect balance.

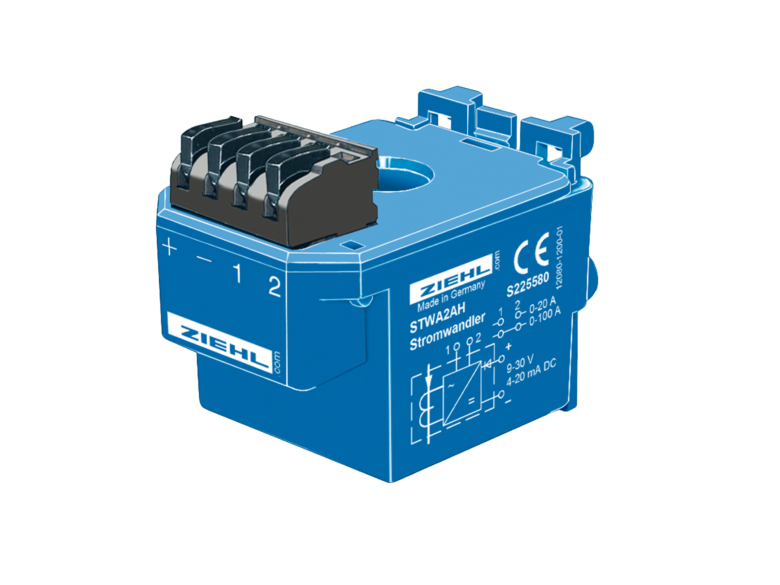

Source: ziehl.com

Accuracy and Precision

Accuracy in measurement is paramount, particularly in applications where precision is of utmost importance, such as medical or aerospace projects. Even a minor measurement error can have far-reaching consequences.

When assessing accuracy, consider other factors like linearity, hysteresis, and temperature drift, as they can collectively influence the overall accuracy of the transducer in real-world applications.

Size and Form Factor

The physical constraints of your project play a crucial role in determining the size and form factor of the current transducer you select. While some projects may accommodate larger transducers, compact designs often necessitate smaller, more streamlined components.

Output Signal Type

Current transducers offer various output signal types, each catering to different applications:

- Voltage Output (e.g., 0-5V, 0-10V): Suitable for most analog inputs of Programmable Logic Controllers (PLCs) and data acquisition systems, providing flexibility and ease of integration.

- Current Output (e.g., 4-20mA): Ideal for long-distance transmission with minimal signal loss, making it suitable for applications that require precise control over current.

- Digital Outputs: Designed for direct interfacing with digital systems or microcontrollers, ensuring seamless integration into digital ecosystems.

Your choice of output signal type should align with the specific system you are interfacing with and the desired signal quality for your project.

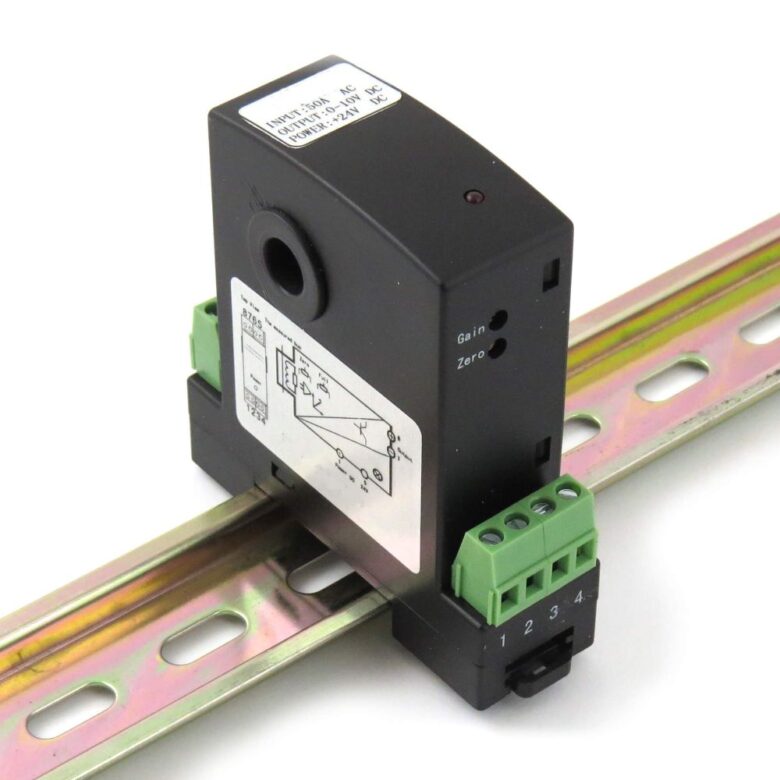

Source: ebay.com.au

Importance of Isolation

In many applications, isolation proves critical to ensure that the measurement circuit remains separate from the monitored circuit. This separation serves as a safeguard against the intrusion of noise, transients, and other unwanted signals that could potentially compromise the accuracy of your readings.

When dealing with high-voltage systems or applications sensitive to electrical noise, always prioritize an isolated transducer for uncompromised data integrity.

Power Supply Considerations

Another vital consideration when selecting a current transducer is the power supply requirement. Determine whether the transducer necessitates an external power supply or if it can operate by harvesting energy from the measured signal itself.

An externally powered transducer may offer enhanced accuracy and a broader range of functionalities but will also demand provisions for a stable power source, potentially affecting your project’s design.

Durability and Environmental Ratings

For projects exposed to harsh or challenging environmental conditions, the Ingress Protection (IP) rating of the transducer becomes a crucial consideration.

The IP rating indicates how effectively the device can withstand and protect against dust, water, and other environmental factors. Choosing a transducer with the appropriate IP rating ensures longevity and reliability, even in adverse conditions.

Balancing Cost Considerations

While cost-consciousness is a natural inclination, it is essential to strike a balance between budget constraints and project requirements. Opting for the cheapest available transducer may lead to compromises in terms of durability, accuracy, and other essential features.

In some cases, investing in a slightly more expensive transducer with superior performance and reliability can result in significant long-term cost savings by minimizing downtime and maintenance costs.

Manufacturer Reputation and Support

The reputation of the transducer manufacturer carries substantial weight in the decision-making process. Renowned manufacturers typically prioritize quality assurance and offer robust after-sales support.

Their products often come with comprehensive documentation, which proves invaluable during the design, integration, and troubleshooting phases of your project. Choosing a transducer from a trusted manufacturer is a prudent step toward ensuring the success and longevity of your endeavor.

Source: denkovi.com

Conclusion

Selecting the right current transducer for your project may initially seem like a daunting task, given the plethora of options available in the market. However, armed with the comprehensive guidelines provided in this article, a deep understanding of your project’s unique needs, and a willingness to seek expert advice when necessary, you are well-equipped to make an informed choice. The correct transducer can serve as the linchpin of your project, ensuring smooth operations, efficiency, and the precision your endeavor deserves. By investing the time and effort into this crucial decision, you pave the way for a successful implementation and, ultimately, the achievement of your project goals.