Environmental test chambers play a crucial role in ensuring the quality, safety, and durability of products under various conditions. As the demand for precision and reliability in various sectors increases, so too has the technological advancement behind these essential tools.

Let’s delve into some of the exciting innovations and intricacies that power these modern marvels.

Contents

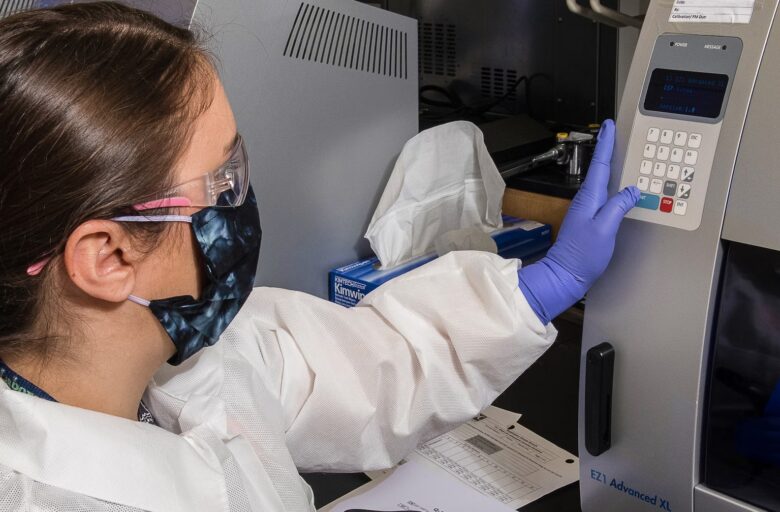

The Evolution of Test Chambers

Source: unsplash.com

Understanding the technology behind modern environmental test chambers requires a brief journey back in time.

Basics and Foundations

These chambers were once straightforward in design and function. They aimed to recreate a specific environment – typically temperature – to test how materials would react. These early models relied heavily on mechanical systems and basic electrical components, with little to no automation.

As industries grew, so did the need for precise testing under various conditions. This spurred researchers and manufacturers to incorporate more advanced technology into their designs, paving the way for the modern, multipurpose chambers we see today.

Integration of Electronics

The transition period witnessed the integration of electronics, leading to enhanced precision and automation. These innovations allowed for better control over test conditions, as chambers could now simulate humidity, radiation, and other environmental factors with remarkable accuracy.

In addition, the integration of sensors and feedback loops meant that chambers could automatically adjust conditions based on real-time data. This not only improved consistency and reliability but also allowed for more complex and nuanced testing scenarios.

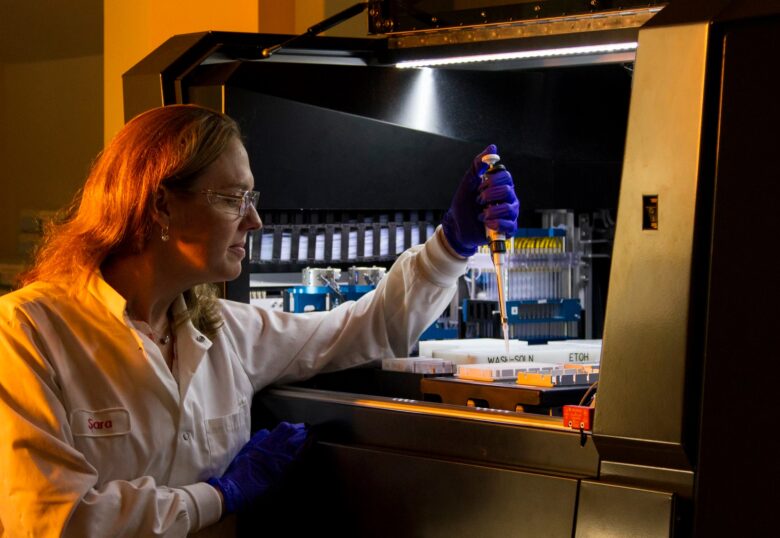

Core Technologies Powering Modern Test Chambers

Source: unsplash.com

At the heart of every environmental test chamber are a set of technologies that make them efficient and precise. Delving into these core technologies provides a clearer picture of how these chambers can simulate a diverse range of environmental conditions.

Advanced Sensor Technology

Today’s test chambers are equipped with a myriad of sensors that constantly monitor and adjust internal conditions. These sensors can detect minute changes in temperature, humidity, and other factors, ensuring that the environment inside the chamber remains consistent with the set parameters.

Beyond their precision, the real marvel of these sensors lies in their durability. Given that they operate in extreme conditions, these sensors are built to withstand intense heat, cold, and moisture, all while maintaining impeccable accuracy.

Computer-Controlled Systems

Computer integration has revolutionized the capabilities of environmental test chambers. These systems allow for intricate programming, enabling users to set complex sequences of varying conditions for extended periods.

Furthermore, with the advent of AI and machine learning, these computer systems can now predict how certain materials will respond to specific conditions, optimizing the testing process. Not only does this save time and resources, but it also provides a deeper understanding of the materials being tested.

The Future of Environmental Test Chambers

As with any technology, environmental test chambers are continuously evolving. The horizon is ripe with innovations, promising even more precision, efficiency, and automation.

Incorporation of AI and IoT

The Internet of Things (IoT) and Artificial Intelligence (AI) are set to be game-changers in the realm of environmental test chambers. The integration of IoT means these chambers can be interconnected with other devices and systems, facilitating real-time data exchange and analysis.

With AI, predictive modeling will reach new heights. AI algorithms will analyze vast amounts of data to predict material behaviors under untested conditions. This predictive power will not only optimize testing processes but also uncover new insights into material science.

Sustainability and Eco-Friendly Designs

As the world grapples with environmental challenges, there’s a push towards sustainability in every sector, including testing. Future test chambers will likely prioritize eco-friendly designs that minimize energy consumption and reduce waste.

Biodegradable and recyclable materials will be favored in chamber construction, and renewable energy sources, like solar or wind, may power them. This shift towards greener technologies signifies an understanding that while testing is crucial, it mustn’t come at the planet’s expense.

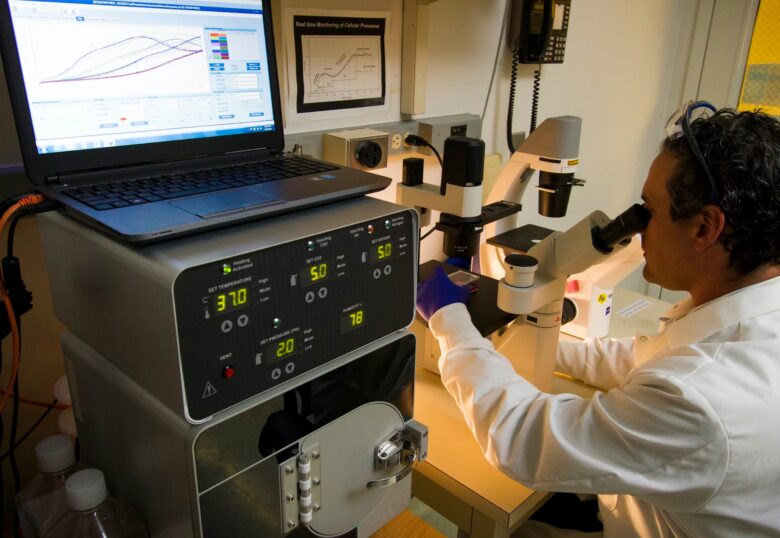

Enhanced User Experience and Accessibility

Source: unsplash.com

The user experience, often overshadowed by the sheer technical prowess of test chambers, is getting the spotlight it deserves. Innovations now focus on making these more user-friendly, intuitive, and accessible to a broader range of users.

Touchscreen Interfaces and Real-time Visualization

Modern environmental test chambers are now often equipped with touchscreen interfaces, making the setup and monitoring process more intuitive. Gone are the days of complex dials and buttons; users can now easily input their desired settings with a few taps.

Additionally, these interfaces offer real-time visualization of the chamber’s conditions. Graphs, charts, and animations depict changes in temperature, humidity, and other parameters, offering a comprehensive view that aids in analysis and decision-making.

Remote Monitoring and Control

With the advent of cloud technology and improved connectivity, users no longer need to be physically present to oversee a test. Remote monitoring tools allow scientists and researchers to view live data, adjust settings, and even conduct tests from anywhere in the world.

This flexibility not only improves efficiency but also opens doors for collaborative efforts. Teams across different locations can work together, pooling their expertise and resources for more comprehensive testing and analysis.

Microclimates within Test Chambers

Beyond replicating general environmental conditions, there’s a rising demand for creating specific microclimates within test chambers. These innovations allow for more nuanced and detailed testing scenarios.

Simulating Altitudes and Pressures

Some test chambers can now simulate the conditions of different altitudes and pressures. This is crucial for sectors like aerospace and mountain sports equipment, where products need to withstand unique challenges posed by altitude.

By adjusting the internal pressure and oxygen levels, these chambers replicate conditions from sea level to the peak of Mount Everest, providing invaluable data for product development and quality assurance.

Dynamic Light and Radiation Control

Another groundbreaking innovation is the ability to simulate various light conditions and radiation levels. Products that are frequently exposed to sunlight, such as outdoor furniture or car interiors, need to be tested for UV resistance and potential degradation.

Modern chambers can vary the intensity, duration, and type of light, replicating everything from a cloudy winter morning to the scorching midday sun in the desert. This ensures products are resilient across a diverse range of light conditions.

Addressing Challenges: Safety and Reliability in Design

Source: canva.com

While the innovations in test chambers are impressive, they come with their set of challenges. Addressing safety concerns and ensuring consistent reliability are paramount in the evolution of these devices.

Advanced Fail-safes and Redundancies

To prevent mishaps and equipment failures, modern test chambers are equipped with advanced fail-safes. These systems detect potential malfunctions and either correct them autonomously or alert the user.

Redundancies, or backup systems, are also integral. In case of a primary system failure, these backups kick in, ensuring the chamber continues to operate smoothly and preventing potential damage to the test samples.

Regular Calibration and Maintenance

Consistent reliability hinges on regular calibration and maintenance. Automated reminders and diagnostic tools are now standard features, prompting users to schedule calibrations or address potential issues.

With the integration of smart technology, some chambers can even self-diagnose and calibrate, reducing downtime and ensuring that they always deliver accurate and reliable results.

Conclusion

In embracing these advancements, industries can ensure that their products are not only of the highest quality but also safe, reliable, and built for the future.

As we continue to innovate and explore, the technology behind environmental test chambers will remain a beacon of progress, reflecting our persistent quest for excellence and understanding.