Computerized Numerical Controls, CNC for short, is a method that is used widely to perform an even wider range of tasks closely connected to the manufacturing industry. These manufacturing tasks are carried out by computerized devices and are a direct replacement to old school manufacturing devices.

As the use of computers is more and more common in our day, the use of CNC machines has increased due to the needs of the manufacturers and clients alike. CNC machining services employ a centralized software that helps streamline work and allows more automated control of traditional tools, which subsequently increases productivity while at a faster rate.

CNC machining services greatly increase production and are mostly used for key industries such as aerospace, scientific instruments, electro-optics, robotics, medical & pharmaceutical equipment, defense, laser systems and equipment, semiconductors, and a wide field of other 21st century technological industries.

Img source: techtanic.com

The CNC machining industry is a highly competitive one due to the nature of the industry to provide a lot of fields with the best quality workmanship with a variety of components manufactured at great speed.

There are many major technological benefits as to why CNC machining services are so important, and we are going to discuss why.

1. Greater Efficiency

Imagine complex tools or devices being handmade, and imagine how much time that would take. With CNC machining, everything is computerized, and computers are used to control the machines. This offers full automated production throughout all major operations and fields, which greatly increases the speed and the quality of the manufacturing. Greater efficiency is something that CNC machining is based on.

CNC machining services, like “Rapid CNC Prototype China Machining Services,” are leading the world in automated manufacturing. These machines can work non-stop and do not require to be shut down. Only in the case of maintenance do these machines need to be switched off, otherwise, they can go on very long time without no break, unlike humans which require brakes and rests, and thus production has to be halted.

Img source: simtiff.com

2. More Accuracy

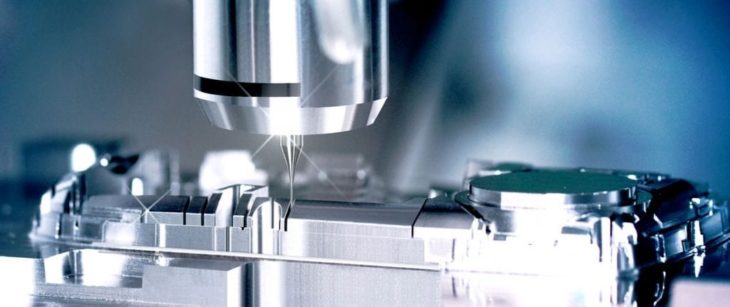

Because these machines are controlled by computers and software, another advantage is that they are more accurate than a human hand. Because CNC machines are operated by computers, and they are programmable, they can focus on every detail of production with great accuracy, where there are no margins for errors. They are so accurate that you can make the same exact copy of a set of tools with no problems what so ever. They offer a more acceptable way of production, due to the demands of clients. And with CNC machines, you can produce tools and parts that otherwise are impossible to produce by a human hand. We, humans, are limited to our capabilities, but there is no telling what is the limitation for a computer.

Img source: baysidemachine.com

3. Fabrication

With CNC machining services, fabrication, or creation, of new tools and parts is crucial. With CNC machines you can fabricate anything through your specifications because they are programmable, subsequently, that makes them reprogrammable, and flexible with any kind of creation. They are absolutely essential for a streamlined production, and they are essential for building the parts that we, humans, simply cannot build. CNC machines are not resistant to damage, so replacing damaged parts can be very hard. With all that in mind, without CNC machines, we would simply concede a major loss that would be rather damaging for our industries.