Stainless steel is a generic term used to refer to a variety of steel types. Stainless steel is made up of iron and carbon in a process that involves two steps. However, what sets it apart from all the other metals is the addition of chromium. It gives plain steel its remarkable properties such as resistance to staining and corrosion.

Typically, stainless steel metal is considered to be alloys embedded with a minimum of about 10.5% chromium. There are also other alloying elements used to enhance structure and properties like strength, formability, and toughness. Such metals may include titanium, copper, nickel, and molybdenum.

The reason why plain steel tends to corrode is that it is made up of iron. In nature, iron usually occurs in combination with some other elements. Therefore, when iron ore is manipulated into its pure form in order to make steel, it becomes unstable and easily recombines with oxygen.

Source: thyssenkrupp Materials (UK)

When plain steel is combined with an amount of chromium, it forms the chromium oxide. This is what acts as a preventative layer to protect the steel from rust. It prevents air and moisture from causing corrosion on the metal. The amount of chromium added is dependent on the application and environment in which the steel will be subjected to. The quantities can range from 10.5 to 30 %.

Generally, there is a wide array of stainless steel grades, as seen on Aero Flex. However, they are divided into five main types:

Austenitic

Source: ThoughtCo

This is the most common and largely used type of stainless steel. As a matter of fact, it dominates the worldwide stainless steel market. This type has one of the best corrosion and resistance properties. It is used in kitchen utensils, medical equipment, and food processing equipment, construction, and architectural facades and can easily be purchased online to fit your needs from FastMetals (https://fastmetals.com/pages/stainless_steel).

Ferritic

Source: The Balance

Ferritic steel contains little amount of nickel, about 12 to 17% chromium, and some other alloying elements like aluminum or molybdenum. When it comes to formability and ductility, this is the (metal) solution most people go for. On the other hand, it is not heat resistant when compared with austenitic types. Ferritic steel is not magnetic but can be treated with heat and strengthened with cold working. It is normally used in boilers, washing machines, and indoor architecture.

Martensitic

Source: Thermo Fisher Scientific

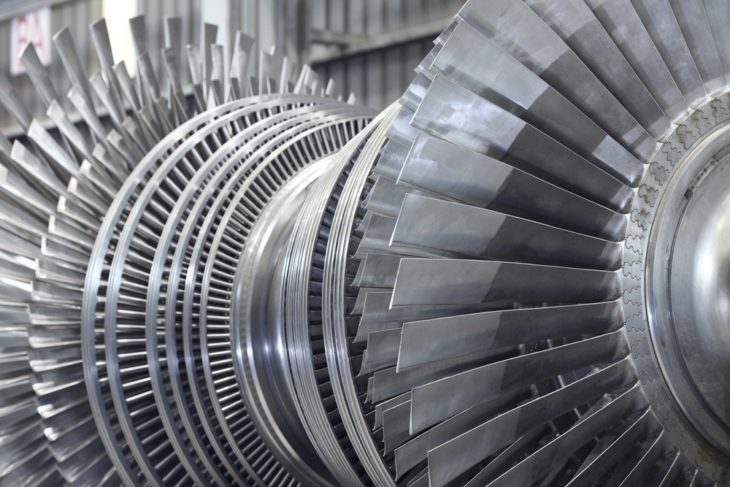

This type of stainless steel is quite hard and strong too. But it doesn’t have remarkable corrosion resistance properties that can be found in Ferritic and austenitic. It contains about 13% chromium, below 0.4% nickel and trace amounts of carbon. The carbon is added to the metal because it contributes to forming and welding. This type of stainless steel is used in cutting tools, knives, surgical equipment, and turbine blades.

Duplex

Source: www.alibaba.com

Duplex stainless steel contains about 22% chromium and 5% nickel with alloying elements such as nitrogen and molybdenum. This type of steel tends to have higher yield strength, and it’s quite resistant to cracking and corrosion.

In all types of stainless steel, resistance to corrosion seems to be the main benefit. However, there are other advantages such as;

● Strong and hence durable

● Resistant to high and low temperatures

● Aesthetically attractive

● Environmental friendly

● Easy to clean and maintain