If you are an electronics manufacturer changes are you know everything about the PCB and its importance. The printed circuit board is there as to bond and support electronic components of one device. And PCBs are used in almost any electronic product you can think of. PCB market value has greatly increased in the past few years and now lies at a fascinating $60 billion.

Thus, if you have a good PCB manufacturer, you won’t have to worry about the usability of your device. Now, with the market growing there have been a lot of companies offering the PCB service, so it is not that easy to distinguish a good from the bad one. After doing thorough research using a few key factors (capabilities, assembly, variety), we came to the conclusion that RayMing PCB Manufacturing is one of the best out there.

Let’s take a look at what makes this company unique!

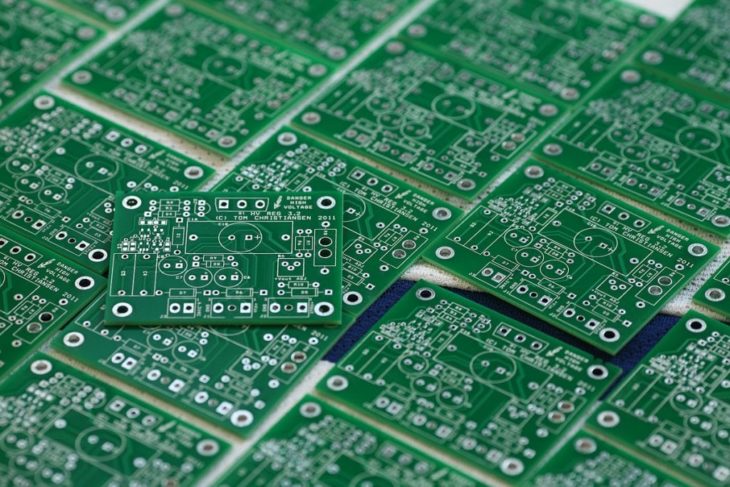

Source: ourpcbte.com

What Does RayMing PCB Manufacturing Have To Offer

First of all, RayMing PCB Manufacturing offers a variety of different printed circuit boards that you can customize and order according to your needs. You only send them the specifications (dimensions and material), and you will receive the product in a matter of few days. Along with that what is great is the fact that RayMing offers a 24/7 customer support in case of any changes or problem. Also, all the circuit boards are done according to the IPC-A600 Class 2 or even higher standards which assure the quality of the given item.

Over 10,000 engineers and 6,000 contractors have done work with the RayMing and expressed their satisfaction. On the other hand in case you are not satisfied with the product you have the chance of sending it back and getting a refund for the same.

RayMing PCB Manufacturing does offer both a full turn and a partial turn-key service. The difference is that if you order a full turn-key circuit board everything is done by the company, while if you order a partial one you can send your parts and RayMing will only assemble the board (of course this costs less).

What is excellent as well is that RayMing tests the finished printed circuit boards through the PCBA function test, as well as the electric test that any board has to pass.

Source: VR Industries

Most Popular RayMing PCB Manufacturing Services

- Standard PCB. Among the most popular boards that RayMing manufactures is the standard PCB one which includes halogen-free, copper, high-frequency as well as the HDI PCBs. The layer number ranges from 1-36, depending on the complexity it can be built in a range from 4 to 30 days, and material that is used is Fr4, Teflon and Rogers.

- Metal Core PCB. This one is the most common is made out of aluminum and FR4, including a thermal layer that allows for better cooling properties. The capacity of layers is from 1-6, and it is mostly used in the high-powered products such as a LED screen.

- Flexible PCB. These have been quite popular for the past few years – mostly used along with other complex components in hard disks and desktop printers. It represents an arrangement of circuity and components that use the flexible material. The maximum number of layers offered is 10, and flexible PCBs are actually pretty small, tight and conventional.

- When it comes to RayMing PCB Manufacturing one of their main services is the assembly. As offered, RayMing can assemble a new PCB from the components and parts you send them. Included in the process of turn-key assembling you will get your printed circuit board in a matter of few days.

Source: shomitrend.com

Summary

PCBs are pretty important in order for an electronic device to work properly, thus investing in high-quality ones is the key. As you can see the RayMing PCB Manufacturing company offers a variety of services, a team of qualified experts and a 24/7 support. What more could you ask for?