Depending on your organization’s needs, there can be a wide range of reasons why you may have to purchase an encoder. However, if you did some digging online before opening this article, you might be feeling completely overwhelmed and confused by the number of options you can choose from.

This is why you might be now wondering – how could I ensure that I choose a suitable encoder for my organization’s needs? Fortunately for all business owners looking for an answer to this question, this article might help. Let’s take a closer look at the things you’ll have to consider in order to opt for the right device:

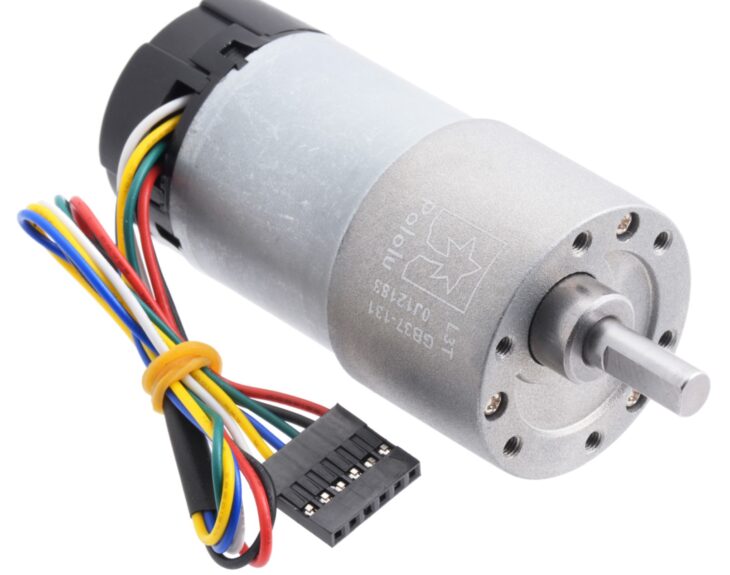

Source: Pololu Robotics and Electronics

Contents

1. Determine Which Type You Need

Absolute and incremental encoders could be utilized for orientation, positioning, as well as speed. Naturally, there are differences between the two options. For starters, an absolute encoder will hold its position after an electricity outage, while the other device will have to go through a process called “homing” after an outage.

If you opt for the absolute model, you should know that it has an option of 16 bits for every turn, meaning that they could provide a better resolution than incremental devices. In general, incremental models are more affordable and the output required is a square wave or sin/cos for the velocity, positioning, and counting.

In most situations, an absolute encoder is utilized for constant motion and it also has other, beneficial features such as scaling, presets, activity, and Fieldbus uses. So, before you move on to the next tip, ensure that you learn and determine what you might need for your organization.

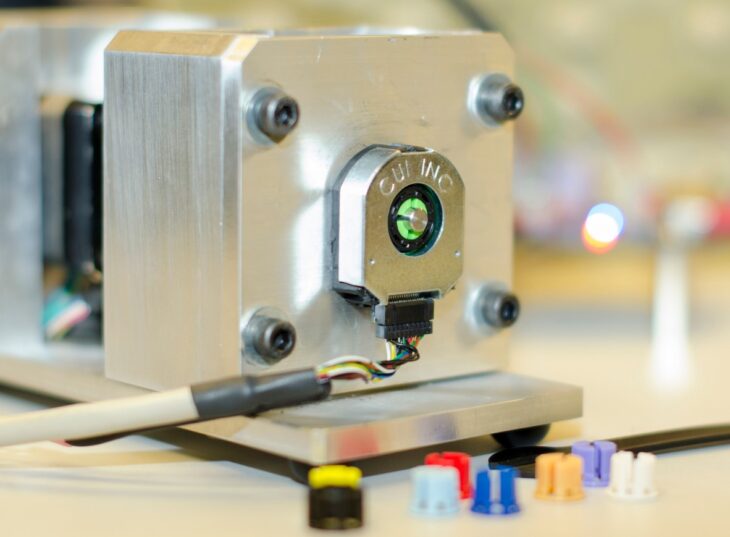

Source: Turck

2. The Output is Important

When talking about the outputs of incremental models, there are several options including OC, line drivers, sin/cos, and push-pulls. The OC is also referred to as an open collector and it has a lower energy and leakage flow than push-pulls. However, a push-pull does have a better slew flow and durability.

Push-pulls could be either NPN or PNP, hence, it’ll be better at properly matching the input of the controller. The line drivers have better durability, which implies that they’re most commonly utilized for longer wire runs. Lastly, the sin/cos is employed for positioning and speed.

With an absolute device, choosing the right Fieldbus is crucial. There are various alternatives you could pick from including Ethernet, Profibus, SSI, DeviceNet, AS-platforms, Parallel, and so on. Keep in mind, the Fieldbus is most commonly determined by the equipment utilized by the organization since they need to match properly.

Source: Robotics Business Review

3. The Application Must Have a Specific Resolution

Depending on the application’s needs, you’ll have to determine what resolution you’ll require. With the incremental option, it could reach up to 50.000 pulses for each turn, and with the other option, you’ll gain 65.536 pulses. To figure out which resolution is suitable for you, the circumference of the moving elements have to be divided by the pulses for each of the turns.

However, the resolution will also rely on the accuracy of the electronic and mechanical parts utilized and it needs to be able to solve any issues that occur and it’ll also have to satisfy the demand. In specific cases, some controllers cannot sustain the frequent response of incremental devices, hence, you’ll have to pick one that has a lower resolution.

Source: baumer.com

4. The Mounting Process

There are various models like the ones featured on Encoder, a Products Company, all of which have different mounting options. However, there are three options that you could choose from including a hollow, solid, or recess-hollow cylinder. For the easiest mounting process, you could opt for the recess-hollow or the hollow models, however, if there’s movement in the handles, it’s recommended that you go for the solid option.

Keep in mind, the solid shaft will have to have suitable coupling since it could help stop the overloading of the bearings. Additionally, there are also magnetic encoders that feature targets that are installed as a hollow shaft, while the sensor is placed close to the magnetic end. This particular type will eliminate any wear and tear, but it still needs to be monitored from time to time.

Source: Thomasnet

5. Think About How You’ll Connect it

You can choose an encoder with a connector or with a long cord. If you opt for a device with a connector, you may have to get a mating connector or a cord set (which is a combo of the cords and connector). This will provide you with a connection point, however, it might not get you to the control cabinet, so, depending on the distance, you might also need a conduit or cable tray.

Source: Motion Control Tips

6. Consider The Amount of Stress on The Devices

If there is one thing that you should remember, it’s that not all encoders offer the same functions. When compared with the models that are more expensive, the more affordable ones usually don’t feature the same mechanical resistance or environmental protection. To determine the amount of stress, you need to think about the mounting process, as well as the resolution you need.

By knowing what you’ll require, it’ll help you with determining how much movement there will be, the speed of the shaft, and its movement since the speed and run-out will influence the exposure of the encoder bearings. You’ll also need to measure the vibration of the machine by utilizing an accelerometer.

When it comes to determining the environmental influence, you should consider the amount and duration of moisture, whether or not there are chemicals used, and you’ll also need to determine the maintenance process. For applications with minimum exposure to moisture, an IP54 rating is suitable, however, if the moisture is present for a long time, then you’ll want and need to go higher.

Source: Green Lighting

Conclusion

The entire process of choosing an encoder for your needs is long, daunting, and often confusing. However, by following the tips mentioned in the list above, you’ll be able to make the entire process easier, less stressful, and more importantly, you’ll choose a suitable option.

So, now that you know what you’ll need to consider when choosing an encoder for your organization, you shouldn’t waste any more of your time. Instead, return to the start of this article, go through it once again, and then determine what you might need for your company.