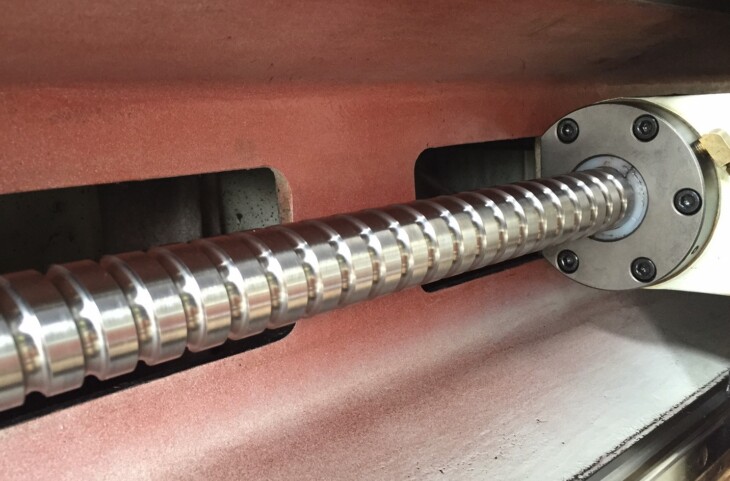

Ball screws are one of the commonest items used for the creation of a wide array of different machines and applications. Machines where you cannot find these are almost non-existent. We mean, just take a look around you, and you will see that we are right when we claim this.

Not only that they are used for the creation of machines that are then sold on the market, but they are also a crucial part of any workshop, no matter how small it is. The same goes for the one people have in their backyard. When you are aware of a fact like this, then you can be certain that the need for this is pretty high. We can see that it only gets higher every year.

So, if you require one of these, be sure to check tuli-shop.com, where you will come across a wide array of different variations. But, before you are ready to decide which one of these you will buy, you will need to understand these different types. Therefore, we would like to elaborate on the concept of the ball screws as a whole. Without further ado, let’s take a look at what we’ve been able to gather up.

Source: Ningbo Imtek Precision Manufacturing Co., Ltd.

Contents

They Can Carry Heavy Loads

We are sure that you didn’t think about how much load ball screws can carry when needed. A vast majority of people are surprised when they hear about how much load some of these variations can carry. Sure, they have a much bigger capacity than some other screws like polymer or plastic nuts. The only type of screws that can carry more than ball ones, is lead screws with bronze nuts.

However, it needs to be said that there’s a high risk of friction after some period. The reason why ball ones can carry so much of it is that they are based on L10 when it comes to the sizing. Not only that this is an opinion, we can see that this kind of size has been scientifically proven as one of the most durable ones. Therefore, it’s no wonder that so many people and companies are interested in using them.

Source: Pinterest

The Question of Mounting

Of course, every engineer needs to account for every project he or she is working on. Therefore, it needs to be said that using this type of screws is one of the best ways an engineer can ensure the quality of the project. Sadly, we can see that a lot of experts are not aware of this important fact. So, they are not using these to a degree as they should use them. One of the most important questions is the question of mounting.

After these are mounted properly, you will see that the fixation will certainly provide a whole new layer of stability to your project. Thankfully, numerous projects have proven this statement of ours. Plus, we are sure that you will have no problem finding these online. When it comes to fixity, there are three different types. We are talking about free, simple, and fixed type.

Going into the details of these three types would be extremely complicated. However, we can say that they are there to enhance the stability and rigidity of the project. Not only that, using these can have a positive effect on column loading, critical speed, and performance as a whole. The only thing we would like to mention is that using the mounts on both ends is an absolute must. Only by doing that, you can ensure complete stability.

Types of Ball Screw Seals

Now, we would like to talk about the types of ball screw seals.

1. High-Performance

There’s not a manufacturer in the world who will not provide you with a chance to use high-performance seals or those who are proper for special conditions. If you take a look at the range, you will see that these can be either double- or triple-lipped seals. However, that doesn’t mean that these two cannot be combined into one. Naturally, it needs to be said that they need to be made of proper materials if you would like them to perform as best as they can.

Source: Scrum Solutions Ltd

2. Non-Contacting

As you can see from the name of this type of ball screws, you will see that non-contacting seals have a small gap. Naturally, that doesn’t mean that this is something that should scare you. There is the type of screws that needs to be used in a certain situation. If you take a look at these, you will see that these gaps have the goal to prevent any kind of friction from occurring in the future. The gap can provide smaller particularities with a chance to fit into it properly.

Source: Birlik Rulman

3. Full-Contacting

Last but not least, we would like to talk about ball screw seals who have complete contact. We are talking about a couple of different forms that have the task of making the contact with outside diameter. The simplest one we would like to mention is the brush seal. Even though users cannot expect to experience so tight contact, it needs to be said that these are good for a wide array of different things. We are talking about scrubbing away and wiping, among many others.

Using these will prevent the creation of the particles, which are better known as ceramic dust, which can hurt the surrounding. The reason is quite obvious, you will not need to apply any changes to them. Instead, you can use them in the same form as they are when you have bought them. Therefore, you will not need to waste your time applying any kind of work on them.

Source: Birlik Rulman

The Bottom Line

While it may doesn’t look like it, ball screws can be a crucial element of your project. Naturally, this is not something that can be seen at the first sight. Therefore, anyone who will need to use these will need to know all about the concept. Here, we’ve provided you with the different types of ball screws, and what you can expect from using these. We are sure you will find all of this information helpful.