As you are probably aware, 3D printers and CNC machines utilize two totally different processes to modify a raw substance into a specific shape. Although 3D printers are increasingly popular, it has some major drawbacks that revolve around mass-producing items, it is limited in the items that you can make, and it is not as fast and accessible as CNC machines.

If you are thinking about acquiring such a device instead of a 3D printer, you might be wondering – what benefits can I gain from Computer Numerical Control (CNC) devices? Well, you’ll be able to find an answer to this question in the article below. Let’s take a look at the advantages you can gain by choosing this option, as well as some other information about these two options:

Contents

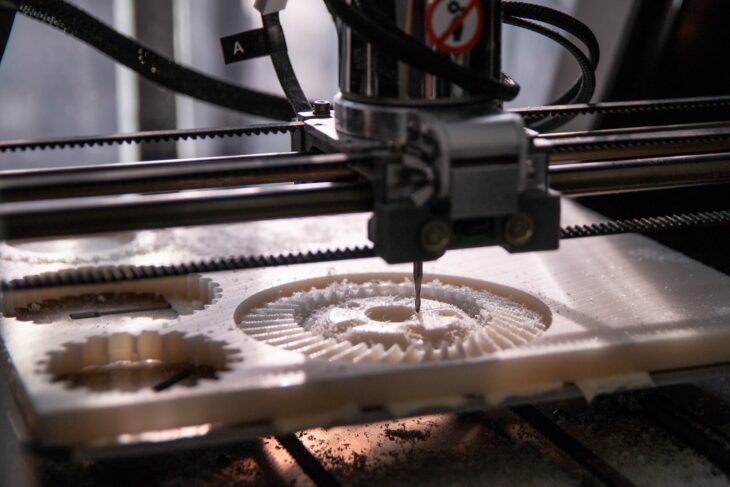

1. It Will Speed up The Production Processes

Source: prototechasia

When you do some digging, you’ll see that CNC machines are faster than 3D devices, especially since it can manufacture a large number of items in a short time. How is this possible? Well, 3D printing builds a component layer by layer, while the other option can create quite fast on the assembly position.

Keep in mind that ‘time is money’, which means that if you need to manufacture a large number of items or components, computer numerical control tools can allow you to do just that – possibly producing hundreds of items for the same amount of time it would take a 3D printer to produce one piece.

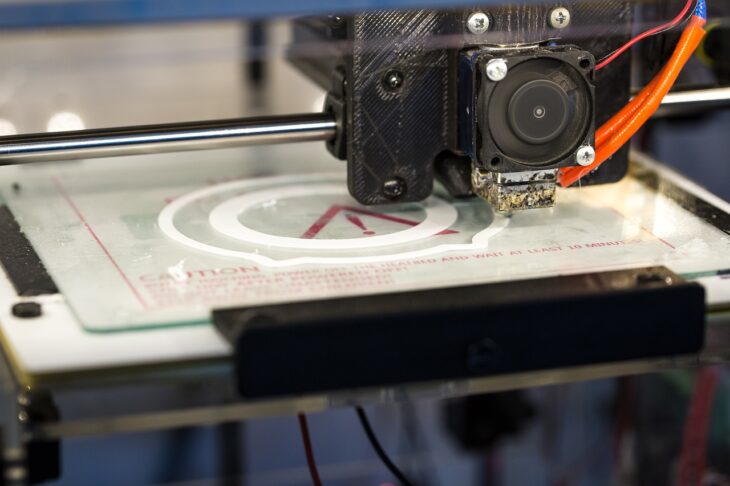

2. A Wide Assortment of Shapes And Sizes

Source: eurocharity

The 3D printing devices can only utilize their production bed for manufacturing elements, however, CNC ones can actually work for creating bigger ones. Now, this does not mean that you cannot use 3D printers for big components, however, in order to do so, the printer needs to manufacture the smaller bits first, and then they need to be assembled later on. According to verycreate.com it is better to choose good quality 3D printers that match your budget and check electricity consumption as well.

This does not only add to the overall production expenses but, it takes a lot of time as well. If you are looking for something that can produce items in a wide assortment of shapes and sizes, a computer numerical control device might be fitting for your production plant.

Luckily for all of us, there are various companies such as cncmachiningtj.com that offer such services, which means that you won’t actually need to purchase the machine but make sure to check a PTJ Shop as well. Instead, you can find a reliable manufacturer that will provide you with the services and things you need for your business.

3. Cuts Expenses And Saves Time

Source: batesmachineonline

Your business might be relatively new, which is why you are probably on a tight budget. This is also one of the reasons why you might want to opt for manufacturing parts by utilizing a CNC device. How does it cut costs? Well, when compared with 3D printers, these machines generate a large number of parts, which means that you won’t need to go through the process several times, as you would with a printer.

Additionally, the time a computer numerical controlled machine needs to generate the items you need will be shorter, which means that you can actually save a lot of time. In return, you’ll keep your clients satisfied by providing them what they need as quickly as you can.

4. You Can Use Various Materials

Source: buntyllc

When you use a 3D printing tool, there are actually only a few substances that you can use such as polymers, some metals, and most commonly plastic. But, CNC devices could be utilized for a lot of other materials including metals, timber, acrylic, different alloys, as well as wax, lather, and so on. This means that a CNC device can actually adapt to any material, allowing you to get exactly what you need.

5. Reliability And Durability

Source: bitrebels

Precision is what you want since manufacturing parts that have flaws can lead to you repeating the entire process, which is something that is extremely expensive. Hence, if you want to ensure reliability, precision, and durability, especially if you are creating parts for the automobile or aerospace industries, opt for using computer-controlled machining.

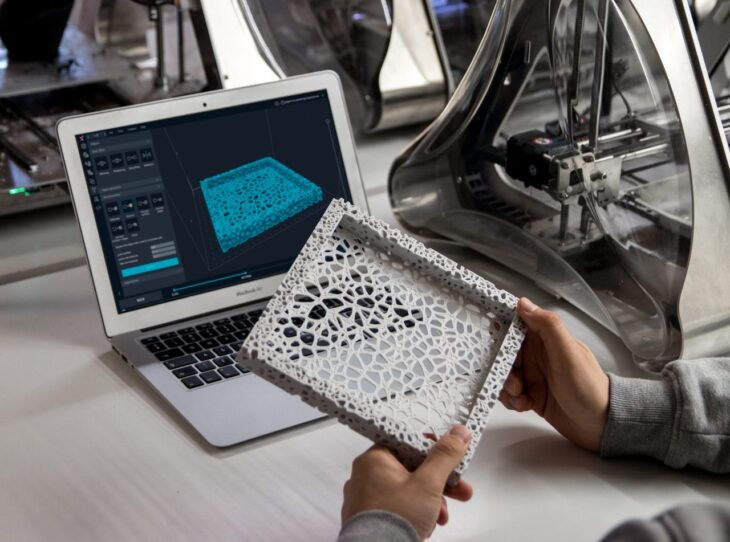

Is There Something They Are Similar In?

Source: medium

Although they are essentially different, both of these mechanisms utilize computer codes for transforming raw substances into the shape of the product you need and want to create. And since they both utilize computers for their processes, the production processes are often consistent and efficient.

So, is There Something to Consider Before Opting For a CNC Machining Company?

There are actually a few things you’ll want to consider doing when looking for companies that can provide you with the parts you need. Before you look at anything else, you must check the reviews posted online. Now, you can do this by looking at the official website, but, you might also want to consider looking at other websites as well, especially since the testimonials there are more honest.

When you create a list of potential companies with good reviews, your next step is to check what services they offer. This can allow you to compare the prices and packages, which means that you can make your list of potential companies shorter. Lastly, ensure that the service provider is a legit business. How can you do this?

Well, you can do so by checking whether or not they posted their business information on their website. Look for an email address, telephone number, or the actual address of the facilities. If there is no such information on the site, you might want to move on to the next company.

Source: highcrossdesigns

Conclusion

As you can see, there is a wide range of benefits that you can gain from using CNC machines. Not only will it speed up the production process, but, it will also allow you to use various materials, as well as create parts in all shapes and sizes, especially the ones that need to be larger.

So, now that you know what you can gain from CNC machining, you should really not waste any more of your time. Instead, you should start browsing online, as well as brick-and-mortar businesses in order to find a machine that will suit your needs and production requirements.