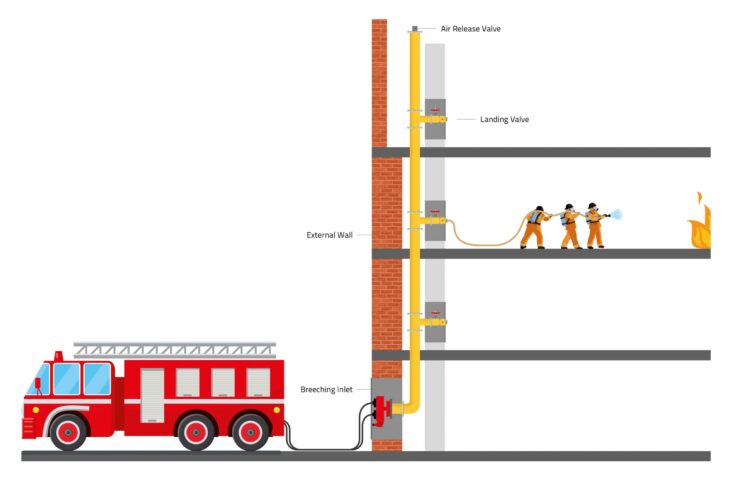

A dry riser system is an empty pipe that runs within a building that firefighters are able to attach and use as water pressurize. Inlet connections are provided to reach fire services on the outside or in the fire escape areas so that water can be pumped up to valves on the top floors. For firefighters who tackle a fire in a multi-floor building, the majority of the systems up to 50 meters above the fire services level are installed. These systems are built to strain a building’s top floors and should therefore be carefully prepared for building construction.

The use of dry raisers is a vital aspect of fire protection in modern high-level design. Fixed systems are used by burners, which provide water for an entire building in the event of a fire. In occupied buildings over 18 m long, dry risers are a building necessity. They can also be found in areas with restricted access or compartmental problems, including multi-level basements or hospital halls. In the event of a fire, the system consists of a pipeline network to supply water to the upper floors of a building. It has an inlet on the field, which the fire brigade may reach to pump water up into the building at a location located on each floor’s landing places. This enables a firefighter to connect the tube to each of these outlets and supply pressure water to extinguish the fire. Multiple companies provide such services such as Dry Riser Solutions

A riser system has the advantage that it is a fixed system in the building and does not need the resources or equipment of the fire service. The three components of the riser system, namely the external inlet, the pipework, and the internal outlets should be constructed to comply with the building approval.

A collecting head that has at least two BS Instantaneous male couplings are typically located in the outside inlet, which allows the connection of fire-fighter water supplies in an external cupboard or enclosure with the dry riser inlet. The cupboard also includes a drain-down valve that allows the dry riser to be drained from the water after or after the fire service. The boxes have to be vandal evidence, but they provide firefighters with immediate access. Doors have normally a breakable area to allow for urgent fire service.

The pipelines of the dry riser system are kept water-free and are expected to be made of galvanized steel. For buildings over 18 meters, the requirements for the internal diameter of the pipe are 100 mm and rise in large buildings to 150 mm. usually fireproof shafts or enclosures contain the pipe. An air valve is located at the top of the tubing that allows the air to be released in the riser when the water is used for charging the device. Internal outlets or landing valves are the link points in the fire brigade that allow the piping lines to be connected and advanced in a building. The outlet contains either an instantaneous female outlet single or double BS, which is operated by a gate valve.

Source: ISON Moulding

Like the exits, the outlets are typically covered by boxes that have also a brisk porch at the door to allow desperately required entry. Outlets are typically placed in a sheltered gateway, stairway, or wardrobe. It is typically one of the fire-exhaust staircases, boxes, or lobbies of the house. One outlet is often placed on the roof to make a test outlet.

Each 900 m floor area, which is not located on the ground floor, should be furnished with 1 outlet and not more than 60 m horizontally apart. In addition, the floor area greater than 60 meters away from an outlet should not be estimated along the path that matches the hose lines. If any of those buildings are deemed the special or specific risk information, details on the size, position, and output of the riser should be included within all risk data and the local fire brigade should be familiar with the layout, purpose, and activity of dry riser in buildings.

Reduce the Risk

Source: Complete Fire and Pumps

As large buildings are designed for commercial purposes, safety considerations must be the first concern of the authority. After work on how the risk of failure can be reduced and decreased in a tragedy, security measures are taken into account. Fire is the most common building disaster. Often incidents are caused by short-circuits and gas leakage. Therefore, in this connection, organizations should take more cautious steps. A dry riser is a significant component of fire extinguishing among many precautionary steps.

How it Works

Source: American Fire Protection Group

A dry pipe fire sprinkler system is in service in a dry riser system where pipes instead of water are filled with compressed air. This pressurized air is kept in a closed position by a remote valve, known as a dry pipe valve. The dry valve is placed in a heated chamber and prevents water from penetrating the tube until a fire drives one or more sprinklers. If this occurs, the air will flee, the dry pipe will open, and the water will reach the pipe and sprinkle to the fire and then extinguish it and prevent it from spreading.

Maintenance and Testing

Source: Tas Valley Fire

Dry risers are a vital piece of security equipment for large buildings and fire fighting. They are built to supply significant volumes of water to the building rapidly and highly. However, it must be protected not only for wear and wear or age failure but also for vandalism as well as all machinery. It is also critical that they are preserved and maintained regularly, which is why it is a legal requirement. A full yearly pressure test plus 6 months’ of visual controls are carried out by the fire and protection solutions to ensure serviceability of the units. And should be checked and maintained annually and either owners or authorities that are responsible for this. In order to ensure that the equipment is prepared for immediate use in an emergency, the device is also recommended not only every twelve months but also visually tested every six months. An annual total wet test including a wet pressure test is also recommended. Dry risers must be tested once a year for at least 15 minutes at a pressure of up to 10 bar, this is the only reliable way to test the equipment.