X-Ray Powder Diffraction is an analytical instrumental technique used in labs around the world for a variety of industries and disciplines that can be used to assess and characterize finely ground materials to determine the phase and the unit cell of a crystalline material. It is used in many disciplines such as geology, environmental and material sciences, forensics, pharmaceuticals and many other industries. XRD can be used to identify structural properties such as crystal structure, specific phases and average grain size. The individual pattern of the crystalline samples act as the data that allows them to compare the patterns and therefore they can be easily identified by a variety of available databases. It uses a machine known as a powder diffractometer in order to carry out these processes. Radiation produced by cathode rays is directed at the sample of the material that needs to be analysed and the interaction of both radiation and material creates diffracted x-rays that can be detected. The detected x rays are subsequently counted and then processed in line with a database of results.

What are the key applications of X-Ray Diffraction?

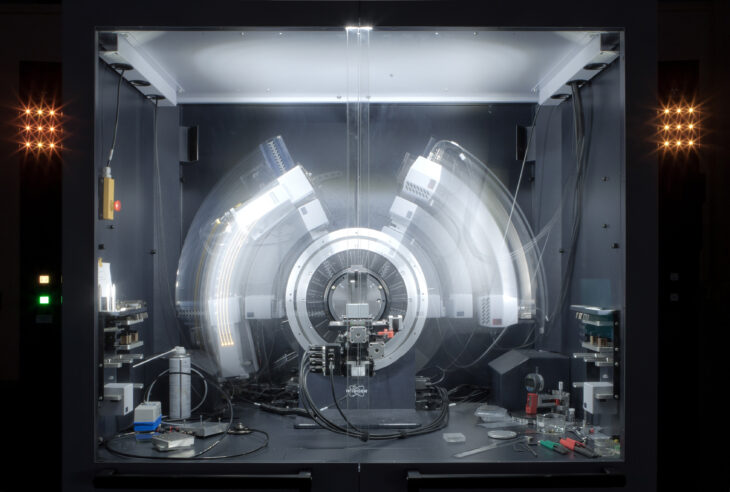

Source: cmm

X ray diffraction is a quick and non-destructive analysis of the mixtures and is a primary method that is used to quantify crystalline materials and detect the acute phases. It is also used for determining the total percentage of materials and determine unit cell dimensions. As well as this it provides measurement of sample purity and can forensically match investigative materials. It uses extreme precision in order to produce the best results and find preferred orientations, structures and phases.

Since x ray diffraction and its associated techniques have been used so frequently used it has produced a database of diffracted materials that can now be used to readily identify inorganic and organic substances alike. The extensive databases with such precise details about a variety of crystalline structures also allow for reverse engineering of competitors products. Another use of this method is that it can create textural measurements such as the average size and orientation of the grains in a given polycrystalline sample. Determining its orientation can allow for further information on its electrical conductivity, thermal expansion and durability.

This technique can show how much of a given material is in a certain state such as glassy or amorphous or alternatively how much is a defined crystal which is necessary information for certain applications and disciplines. This is important as there are such a wide number of different and uniquely structured materials and for individual subject matters it is important to have quantitative data regarding a specific sample to carry out further work. This is particularly useful in pharmaceuticals and earth sciences. In addition to this if you extract the peak positions of the patterns within a given test sample it is possible to quantify the exact amount of each phase present. With such exact and precise results it allows for forensic matching of investigative materials with exact quantitative results.

Pros and Cons of X Ray Diffraction

Source: wikipedia

Some of the pros of using X ray diffraction is that it is extremely powerful and allows for rapid quantification of previously unknown materials without having to do extensive sample preparation beforehand. X ray powder diffraction is also a widely available technique meaning the results achieved will be widely recognised and able to be compared amongst labs and professionals. It is a non-destructive method, which ensures preservation of highly valuable samples. It also produces quantitative measurements that are objective, focused and easily comparable in order to effectively analyse them. Additionally it can be used in quality control through its analysis of individual breakdowns of material structures with unambiguous results.

Alternatively, some of the cons are that it is typically a bulk analysis technique that requires a larger amount of minimum sample size than other techniques which often does not provide as much in depth analysis or depth profile data. This is also an issue as it requires a minimum of a few tenths of a gram of your chosen crystalline material which must then be ground into a powder as opposed to a smaller sample where you do not have to alter it. Sometimes a more comprehensive method of data analysis may be necessary afterwards to determine, analyse and utilise the results to its full effect. This is particularly the case with forensic analysis that may have smaller sample sizes available.

The fact that x ray diffraction produces quantitative results and research has lots of benefits for the usage areas it requires as it is typically unbiased. One of the main ones is that its larger sample means that a broader study is possible leading to an ability to generalise its results. The results also have few variables so it is highly accurate in comparison to a qualitative data pool. Additionally quantitative research can more easily be retested and checked by matching the original variables if there are any anomalies or discrepancies in the results. Quantitative data is also more easily/rapidly collected analysed as it is largely numerical and statistical, allowing for the data to be put into existing equations to problem solve. It can be argued that quantitative data produces a narrow data set due to the limited variables. Finally, the risk with quantitative data is that it may not be fully representative of the whole sample.

Conclusion

In conclusion, X ray powder diffraction is an effective and rapid method of obtaining quantitative data about crystalline materials such as its structural properties and specific phases that can be used across a wide variety of industries for material analysis to eventually be compared across a variety of in depth databases.