While fuel is crucial for all industries today since production and transport of resources is not possible without energy, the biggest issue is related to the environment since the consumption of fuels leads to terrible consequences for the planet.

Moreover, electric vehicles might be a big trend in recent years, but we have to understand that the process of full replacement of combustion engines will require 15 or 20 years. Therefore, increased fuel consumption will remain a problem.

The great thing is that engineers from different parts of the world are working on creating a much safer alternative for petrol and diesel. Some recent discoveries might help companies to produce renewable fuel, green gas, and even save money on fuel. You can read more about this if you click here.

The main issue with renewable gas is that a lot of people never heard about it. Therefore, this concept might sound unreal. Still, the current results are showing that it might be the future of the petrol industry since it can be even more efficient and save that electric engines. We are going to analyze more on this topic in the following article.

Source: japantimes.co.jp

Contents

Types of Renewable Gasoline

When it comes to the types, they are related to different purposes. The reason why companies are creating different models of green fuel is that it can be used for both petrol and diesel vehicles, but also heavy machinery, airplanes, and more. The renewable diesel represents a compound created from biomass.

Also, there is the most recent innovation introduced by the company called Nacero, which managed to create a special version of petrol by adding biomass and ethanol, which leads to much better features where only traces of carbon dioxide represent the existing amount in nature. This cycling process of CO2 is crucial since this fuel does not release toxic amounts of it into the air.

The implementation of this technology is even more important in the airplane industry. The interesting fact is that one average international flight waste more fuel than all racing bolides in the F1 championship for a whole season. This special version of jet fuel represents a combination of kerosene, biomass, and different types of additives that makes it safer for the environment.

Source: inf.news

Methods of Production

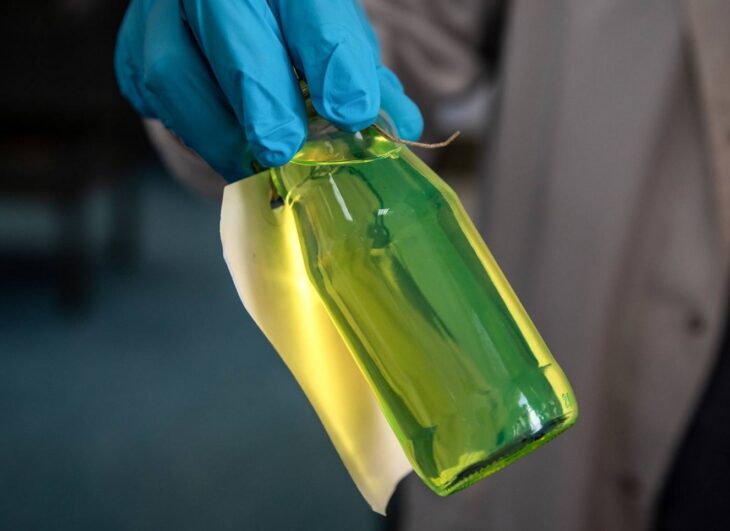

Different sources can be used for the production of green fuel. The crucial part is that gathering these resources does not require traditional models that include taking out any resources from the ground. These much safer and more efficient alternatives are animal fat, grease, vegetable oil, algae, wood, crop, and more.

All of these materials are treated with various processes to produce a compound similar to standard gas. For example, hydrotreating is used to create fuel from fats. There is also a process where ethanol is created in biomass, which is providing it with features similar to fuel. There is also a gasification process where biomass is treated with carbon and high temperature. Other common methods are hydrothermal processing and pyrolysis.

Source: biofuels-news.com

Main Benefits

It is simple to understand the advantages of these innovations. First of all, the fuel created from biomass provides almost the same features as standard gas. Therefore, you can simply start using it no matter which type of vehicle you have. There are different types specially designed for petrol and diesel engines, and there is no need for additional upgrades.

In that matter, it might be even more efficient than electric vehicles. The problem with electric cars is that they can be quite expensive. Also, there are some other challenges like limited range and the need to charge the car more often.

On the other side, the industry can increase the production of green fuel to the point where it can completely replace the standard type. That is a much cheaper and more efficient solution. The emission of toxic materials is even lower when compared to electric cars. The reason for that is that a lot of countries are still using outdated methods to create energy, like coal.

Source: azocleantech.com

Expectations for the Future

Scientists are working for a long time on this innovation, but it is not so simple to replace the current options since it is a huge industry. However, recent global challenges and crises that affected the industry to face record-high prices of gas have led many companies to invest more time and money into detailed research and new programs that will help them to make biomass fuel production much more efficient.

The most recent discoveries and trends are showing that using soy-based additives and ethanol, along with other ingredients like corn, sugar, and fat, can lead to significant changes in the industry and allow companies to create a much cheaper alternative to fuel that has the same of even higher efficiency.

The key feature of this fuel is related to the amount of CO2 in it. The most recent methods allow them to create fuel that will contain only the amount of carbon dioxide that was already in the ingredients used in the process, while the combustion process won’t lead to additional production of this toxic substance.

Source: physicsworld.com

Last Words

The essential part is to let people learn more about this alternative and for the governments to invest more and motivate companies to work on these innovations. However, we have to beware of the challenges. The production of this alternative will require an investment in new technologies. Also, existing fuel companies might not decide that easily to give up on huge profit they are making by selling standard fuel.

However, the raised awareness and interest of people to start using the alternative fuel is the best way to motivate more companies into changing the current production practices. Most people are talking about electric cars these days, and they indeed are clean and convenient.

However, the fuel created from biomass can be an even better solution since it is also safe for the environment, but it can be even cheaper for production, while there is a chance for the current infrastructure to remain, like gas station and vehicles that can use green gas.