Silkscreens have become one of the most popular polymeric dough techniques in the latest days. They let you construct your personal imprinted “textile” of dough and are a pretty cool technique for creating a pattern that you can subsequently utilize in an alternative manner in your endeavors.

Whereas the basic concept is straightforward, there’s a lot to learn about operating silkscreens on biodegradable polymers. There’s still plenty to remember that we knew an article wouldn’t be able to cover all. Silkscreens are only the commencement, but meanwhile, let’s look at how to use them effectively.

Contents

How To Utilise A Silken Print With Biodegradable Polymers In Step-By-Step Instructions

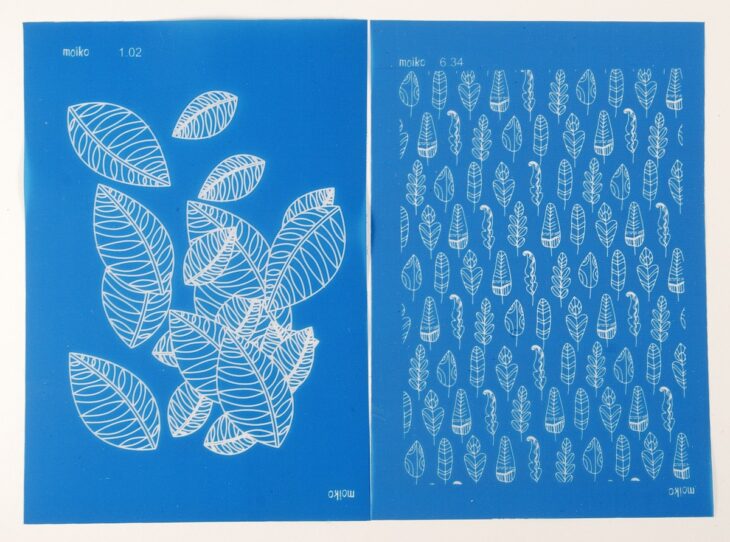

Source: thebluebottletree.com

Silkscreens are cutouts made from a tiny weave of the cloth. To imprint a picture onto a substance like cloth, plastics, polymeric dough, or sheet, you press pigment through a screen. Although silkscreens could be used to print on various materials, we’ll concentrate on how they function here. So come on visit this site and get your Screen Printing Equipment.

- Stretch out your polymeric dough to the desired thickness to achieve the desired depth.

- On the pinnacle of the dough, place the silken screen. To keep it stable and lightly press it.

- Pour a little quantity of acrylic onto the screen.

- Distribute the pigment uniformly on the silken screen’s base with an old bank card. As if you’re attempting to force the color through into the screening and onto the dough, pressing down. Use no metallic instruments or something pointy that could harm the silken screen’s texture.

- If you’re using a powdered substance, whisk it over the screening with a delicate paintbrush and press it onto the dough. Certain mica dust or shimmering pigments may help if the granules are too large. First, put it into practice!

- Evaluate your performance by lifting a border. Continue working on the dough.

- When you’re prepared, pull one edge of the screen to remove it carefully.

- Put the silken screening in the liquid as soon as possible, in either a water jug or simply in the basin. Rinse the pattern with iced water till the color vanishes.

- Please don’t rub it too vigorously to prevent damage to the screen. The idea is to eliminate all of the pigment before everything hardens off; otherwise, it will block the small pores and prohibit your display from working. The painting will naturally discolor the display; ensure it does not obstruct the pattern.

- Using a hand towel, pat thoroughly.

- Allow the silken screen to rest flat before storing it.

- Allow time for the balsam to cure the dough.

Guidance For Using A Silk Screen

1. Explore Silk Panel In Many Classic And Fresh Versions

Source: holdensscreen.com

We advise you to transition to a newer printing fabric that has exposure on both surfaces and doesn’t have a visible shiny side. While putting paint on a stencil, you can utilize either face of the screen. This also gives you the option of creating reflections of designs using both surfaces.

Create a border across one of the edges. Using a spatula or an old bank card, pull the pigment from across the pattern. By progressively raising from one edge, you can eliminate the pattern. Don’t be afraid to be inventive; it will make your work more authentic.

2. Cleansing

Always keep an eye on the structure and the sanitation throughout the procedure to avoid any mishaps. Allow the pigment on your stencils to dry before removing it. Immerse your stencils in a jar of water that is close by. If required, carefully wash your fabric screening with soapy water.

If necessary, lightly massage the paint away with a gentle cloth. Use smooth fabric to avoid rubbing off the emulsified and ruining the pattern. As a result, extreme caution must avoid wiping or wearing off your artwork.

Place glossy face up on a cloth or hanging stand to dry. If many decals become stuck combined, do not attempt to separate them. Soak the designs in cool water to loosen them up. Using normal tap water, clean the decals. Use lacquer thinner cleaner, acetone, or oil-based color exfoliator if required.

3. Specific Suggestions For Polymer Clay

Source: en.wikipedia.org

Acrylic that contains too many superplasticizers stays tacky and does not dry correctly. Because the thermoplastics make the ceramic flexible, the finer the dough, the more probable it will be a problem. We propose to use Kato mud, which would be the lowest squishy of the top brands.

It will not settle adequately if your pigment is not fully dry in ten minutes following silkscreening. Having to wait longer only exacerbates the problem since the paint continues to interact with the pozzolans. We recommend finishing your product design and putting it in the ovens as quickly as possible to avoid this.

4. Storage

It is among the most significant pieces of advice one can receive. Stencils should be stored straight, not folded or bent. Zip-lock sacks or a container can be used to keep the items. You do not want to muddle up the design.

5. The Causes And Remedies For Poor Printing

Source: 3rdrailclothing.co.uk

Underneath the screen, pigment bleeds:-

- The paint was not applied thickly sufficient. Using heavier paint is a good idea.

- The silk screening is not establishing a good appropriate grip with the shiny surface. Use screen printing glue sprays as a last resort.

The painted layer is excessively irregular:

- For a great match, cut the silk screening into small chunks. Sealing down could be beneficial.

- An excessive amount of pressure was given to the brush or spoon. Apply less force to the paint if it isn’t going in

Mesh is being filled with dry paint:

- Before beginning, wipe the silken screen (as described previously).

- The pigment is too heavy. Paint has colors or tiny dots which are too big to pass through the lattice.

Conclusion

Many retailers offer silk screening with pre-printed designs on them. Those models are ideal if you’re in a rush or don’t have the confidence to make your unique silkscreen patterns. However, many painters are hesitant to use another creator’s ideas in their production. Making your customized silk screening with your designs is the answer. We hope you’ll do the same for yourself.