If you are running a company where a lot of farm work is involved you know the importance of buying the right equipment and adequate machines that will result in effective mass production. Excavators are probably the most useful machine when it comes to farm work, and with adequate maintenance, these can last you for years to come.

Now, as you might be familiar excavators are propelled by two main things – metal tracks and two final drive motors. While taking care of metal tracks is not that demanding, you need to put more work in maintaining excavator travel motors and getting the most life out of these. Final drive motors are said to last somewhere between 5 to 7 years, and with the proper maintenance, it can be even longer. And of course, as you know the excavator travel motors aren’t a cheap thing so you will want to make your investment worth it.

Without further ado let’s go ahead and take a look at the few tips on maintaining your excavator travel motors!

Img source: AVSpare.com

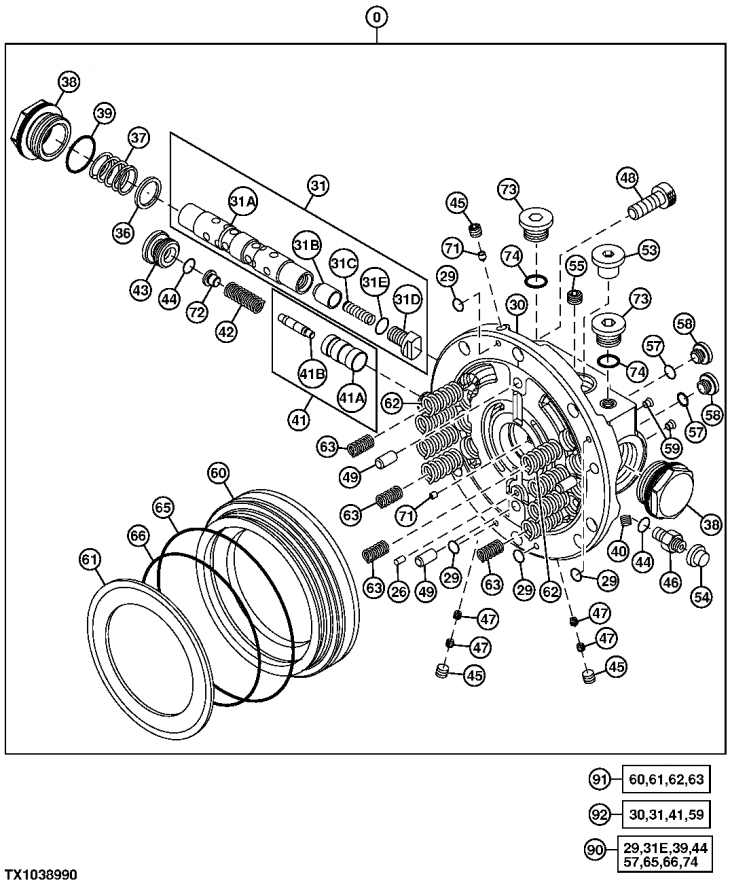

What Are Common Failure Parts In An Excavator Travel Motor

Before moving on to prevention let’s name a few common cases of a motor failure. First and foremost you should know that the main bearing is usually the most responsible for a final drive motor failure and that you should replace it as soon as you start hearing more noise or vibration in that area. Making a mistake and leaving the problem unnoticed can cost you a few thousand dollars (cost of a new motor). Along with that, comes the wearing of gears and related bearings as the second most common problem – after years of use gear teeth will be worn out and you should replace it before any further problem occurs. Let’s not forget that upper and lower shafts, along with seals that are leaking are pretty common and something that you should check on a regular basis.

As soon as you hear that your machine is producing more noise than it was before while being less effective it is time to take a look at your motor and see what can be done to save it.

Few Prevention Tips

Most of the damage on excavator travel motors could have easily been prevented by proper maintenance. Now, first and foremost one of the most important things is to clean it on a regular basis. Once your excavator gets in all that dirty and muddy job, the motors will suffer, and you should be cleaning them out with a lubricant after the session is over. This will keep your motors well oiled and free of any dirt and debris that can pile up and cause further problems.

Img source: komatsu.co.za

On the other hand, and as mentioned above prevention is the key so unless you want to buy a completely new motor of neglecting a leak problem you should invest into resealing and stay trouble free. As soon as you notice a crack in the seal take it to repair, pay those few hundred dollars but know that you saved yourself a few thousand in the process.

Summary

Excavators are essential in your farm business, and a few good ones could last you a long time with proper maintenance and high-quality motors. Investing in good final drive motors from the right supplier will go a long way. And you don’t even have to buy it directly from an official dealership – there are more than a few online retailers that sell the same quality at 50% off the price!