Distilled water is water that has been purified by being heated to high enough temperatures to evaporate any impurities. Distillation is a method for purifying water by removing impurities by heating it to a degree close to the point of boiling and allowing the steam to escape.

When the steam is collected and allowed to condense into freshwater, any minerals and contaminants that may have been in the source water are flushed away. Distilled water is used extensively in places where sterility is of paramount importance, such as hospitals, labs, and factories, because of its unusually high purity. It can also be used in humidifiers or irons to prevent the buildup of minerals that can cause damage to the equipment over time.

Contents

- The Process of Creating Distilled Water:

- Simple Distillation:

- Multi-Stage Flashing Distillation:

- Fractional Distillation:

- Why Is Distilled Water Necessary?

- Cosmetics Industry:

- Acid Batteries and Auto Mobile Cooling Systems:

- Medical Applications:

- In the Food Industry:

- In Fish Tank:

- Environmental Impact:

- Set Up of Distilled Water:

- Role of Maintenance Play in Making Distilled Water?

The Process of Creating Distilled Water:

To produce distilled water, one must first heat the water that will be used as a source to a boil, then allow the water vapor to cool down and condense before collecting the resulting liquid. These three processes account for the vast majority of water distillation operations.

Source: insider.com

Simple Distillation:

Condensation is the first step in the basic distillation process, which involves raising the water source to a temperature that is higher than 100 degrees Celsius, allowing the steam to rise via a condensing space, tube or wires, before collecting the purified water. Condensation is the first step in the basic distillation process.

Multi-Stage Flashing Distillation:

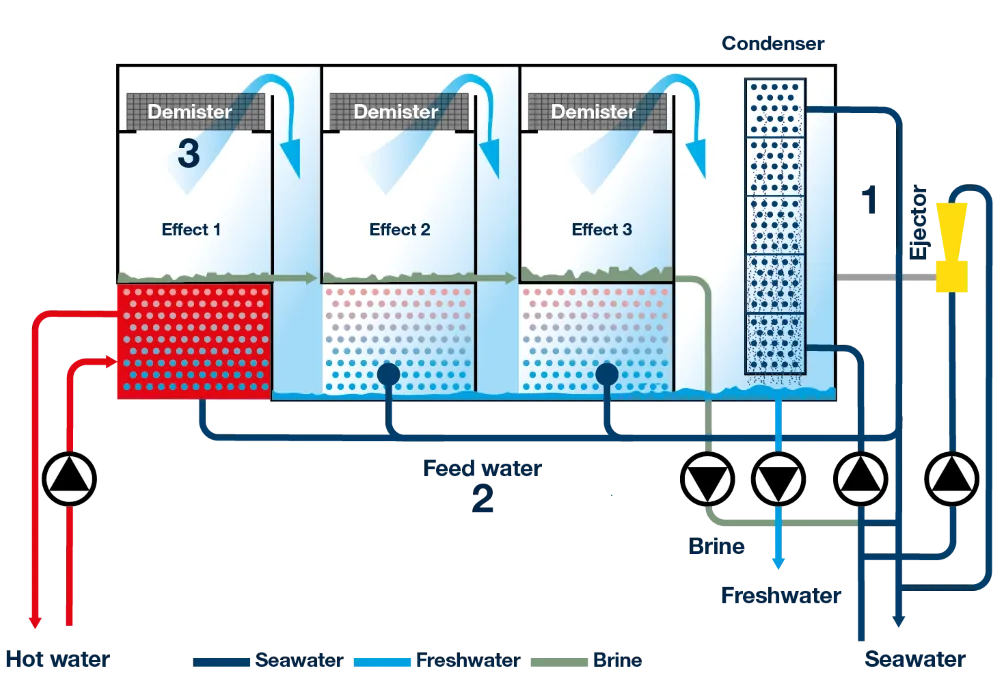

MSF, which stands for multi-stage flashing distillation, is a process that separates a wide variety of compounds from a liquid by applying intense heat and pressure. This triggers it to instantly turn into vapor at room temperature, and there is no need for any additional heating because of this. The steam in a room will turn into a liquid when the pressure inside decreases to a low enough level.

Fractional Distillation:

It takes advantage of the disparities in temperature that occur during the heating, evaporation and condensation processes. This is not something that is done very frequently with water due to the fact that its boiling point is always the same, however it is a common technique in the refinement of petroleum due to the fact that all of its parts have boiling temperatures that are all over the place.

Source: wartsila.com

Why Is Distilled Water Necessary?

The sterilization using water that has been through the distillation process can be beneficial for many different products, among which are used in medical care, batteries made from lead acid, vehicle cooling systems, and various other goods where mineral deposits could potentially cause damage. Because of its exceptionally high level of cleanliness, it is an excellent choice for use in the production of cosmetics, the storage of food, and the sterilization of laboratory equipment.

Cosmetics Industry:

The use of distilled water is recommended since it does not contribute any bacteria, chemicals or other pollutants that could be potentially hazardous to the end product.

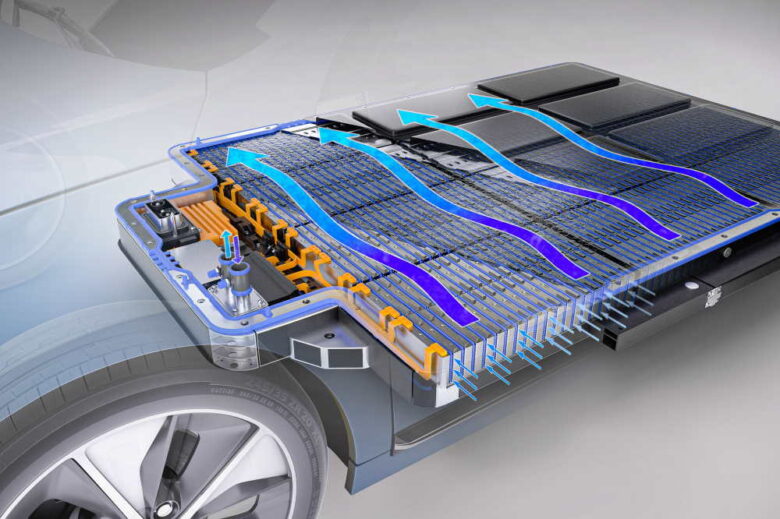

Acid Batteries and Auto Mobile Cooling Systems:

Both lead-acid batteries and car cooling systems are affected by the existence of dissolved minerals. Distilled water may be used to avoid corrosion or buildup in these systems, which are both influenced by the presence of soluble minerals. Lead-acid batteries are used as a cooling source for a wide variety of equipment found in commercial or military vehicles and equipment.

Source: fst.com

Medical Applications:

The distilled form of water is the liquids preferred for cleaning technology utilized by the medical business due to its great purity & lack of any residue or deposits. It is utilized by surgeons to disinfect wounds and by first responders to prevent infection and cross-contamination.

Dentists use filtered water to remove microorganisms from patients’ mouths after dental procedures. The use of distilled water in Constantly Positive Airway Pressure (CPAP) machines is beneficial since it inhibits the growth of germs and other microorganisms.

In the Food Industry:

Canning with distilled water helps to maintain the product’s authentic flavor even after it has been stored for an extended period of time. The minerals and salts that are left behind which is not distilled water can potentially have an effect on the flavors.

In Fish Tank:

Because of the inclusion of minerals along with additional impurities, fish kept in aquariums should avoid drinking water from the tap. Because the pH and salinity levels of distilled water may be adjusted, the water can be adapted to meet the requirements of the marine organisms that is being maintained.

Source: aquariadise.com

Environmental Impact:

Every day, over sixty million water bottles are discarded and sent to landfills. All of this disposable plastic has a shockingly large impact on ecosystems. If you distill water at home instead of buying bottled water, you can save money and cut down on waste. You can take your water with you anywhere thanks to high-quality stainless steel water bottles.

Commercial water distillers ensure that businesses always have access to pure water for their staff and consumers. Because of the enormous need for bottled water all over the world, a significant number of plastic water bottles are discarded in landfills, and it takes a significant amount of resources and money for getting those bottles to various places.

Set Up of Distilled Water:

Distillation water unit installation requires a flat, ventilated area and constant access to electricity. The devices for self-refilling need to be close to a source of water. You may hide the unit out of sight and yet have access to distilled water whenever you need it by purchasing the optional demand pump.

Role of Maintenance Play in Making Distilled Water?

Under typical conditions, the units require almost no upkeep. It is recommended to drain the boiling tanks once a week (the automatic drain mechanism take handle of this for you) after boiling the water to remove pollutants.

Source: wired.com

You should clean the boiling tank at least once in a month, and possibly more often depending on the quality of the water where you reside. Carbon fiber post-filters should be changed out every three months.