The preparation of each final product requires great preparation by one company. No matter what the product is, companies need to be well prepared to make it. This means that companies need at all times to have all the necessary components, ie materials for construction, it is necessary to have the necessary number of workers for that task, as well as it is necessary to have the necessary machines, tools, or equipment with the help of which the final result will be reached – finished product. Whether it is a product made of iron, a combination of iron, plastic, or just plastic. Special care is needed when it comes to plastic products.

Plastic products are especially interesting. Why? Because their production requires, first of all, a lot of attention from the workers, then special machines are needed with the help of which the final product can be reached, special materials are needed to be purchased to get a good final product and every process needs to fit well to get a great end product without any mistakes. One of those well-fitting processes is the Plastic Injection Molding Process which is perhaps one of the best processes that in the end give the final product without mistakes and without flaws. This process is very interesting for everyone, and we are sure that you have wondered how it all works. Today we will talk about that, we will try to explain to you through a few steps what kind of process it is, and in the meantime, if you want to learn more about technology go to plasticmold.net and find out what kind of technology it is and what its features are. And then? Then continue here, as we bring you in detail how this process goes. So let’s see what it’s all about.

Source: cnhaijiang.en.made-in-china.com

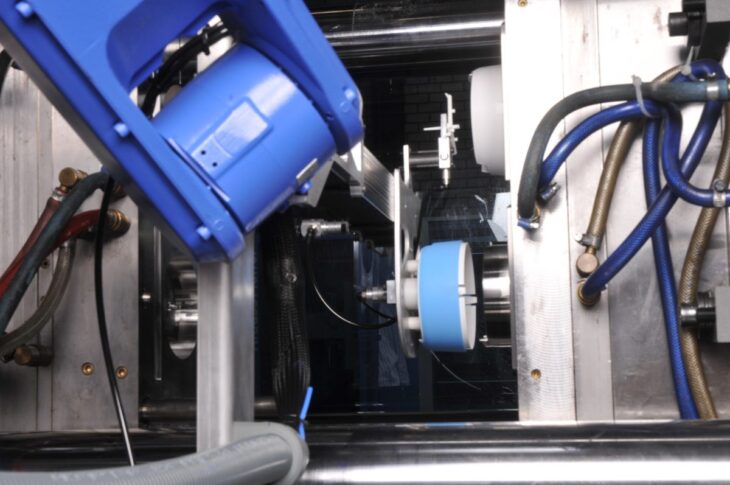

- It is necessary for the company to have the appropriate equipment that will be in charge of making the final products – to get the final product it is necessary to have the appropriate equipment that with its work will lead to obtaining the final product. Not every equipment is good enough for this process because outdated models often make a lot of mistakes and give a lot of end products with errors while new machines are well programmed to avoid errors, faulty products, production runs faster and thus the performance is better. and in large numbers, which means only that the company will successfully respond to any task set before it in terms of making plastic products.

- Suitable quality consumables are needed for making plastic products – it is also necessary to have everything needed from consumables for making plastic products. Thus, certain oils are needed for the lubrication of the machine and for its maintenance, in addition, it is also necessary to have a suitable plastic material, and these are the granules that the companies that do this kind of business procure. These granules need to be inserted into the machine and melted and combined into a mixture from which final products and workmanship will then be made which will then be sold or delivered to customers.

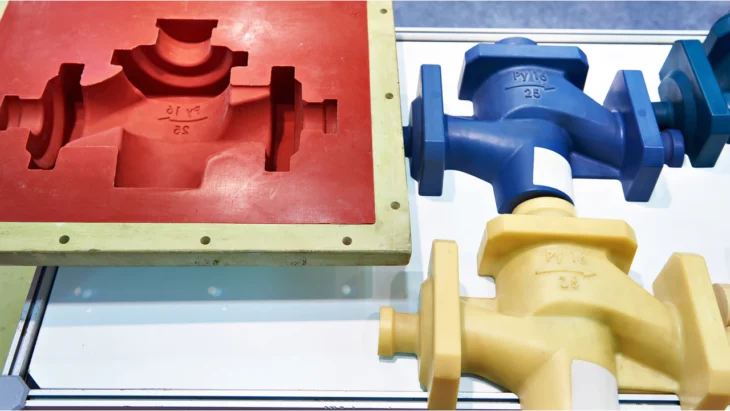

- The form in which you want the product to be made is chosen and of course the quantity that should be made is chosen – every company that deals with production has a daily norm of production that it has to fulfill according to what is ordered and according to the deadlines. This is also the case with companies that produce plastics. They must deliver the finished product at a certain time and in a certain quantity, so the next step is to choose the quantity to be produced in the production process as well as the form in which the product is to be made. The shape can be easily determined on the machine itself, while the quantity is also determined by entering the units you want to get at the end of the machine operation, which is an advantage for new machines.

Source: Medium.com

- Then the machine melts the plastic and makes products in the desired shape – then follows the process of melting the plastic and getting the final result. The machine melts the plastic at a certain temperature until it is combined into one mixture and a mixture is obtained to make the product. Then, according to what is inserted in it, the products that were ordered by the client are produced by injection process. These products can often be made in irregular shape, but this can only happen with 2 or 3 copies of the whole series which is not a problem at all. However, it should be emphasized that in this process of melting and making the product in the desired shape there is not too much waiting but that it all goes quickly and simply.

- At the very end we get the final products that need to be checked and packaged – at the end of the operation of the machine we have the finished products that need to be checked. The injection process gives excellent finished products, but at the very end you have to check if everything is OK with them. However, despite the fact that this is a newer way of making products, even though it is mostly about the use of newer machines, it is necessary to know that there may be some small errors in the products that need to be set aside. . That is why it is always necessary to enter a larger number of products before the machine starts making the products so that the wrong products can be replaced.

Source: alligator-plastics.com

Special machines are used for this process, which you can find out in the source of information that we pointed out to you above, and now you are already familiar with how this process goes. Now you know how much better this manufacturing process is and is appreciated by the manufacturers because it is faster, simpler and has a lower error rate which is great for any company that makes plastic products.