Laser marking machines have become an increasingly popular technology in recent years due to their precision, versatility, and speed. They use high-powered lasers to etch or engrave a wide range of materials, from metals and plastics to ceramics and glass. The applications for these machines are endless, and the technology has been embraced by a variety of industries.

Contents

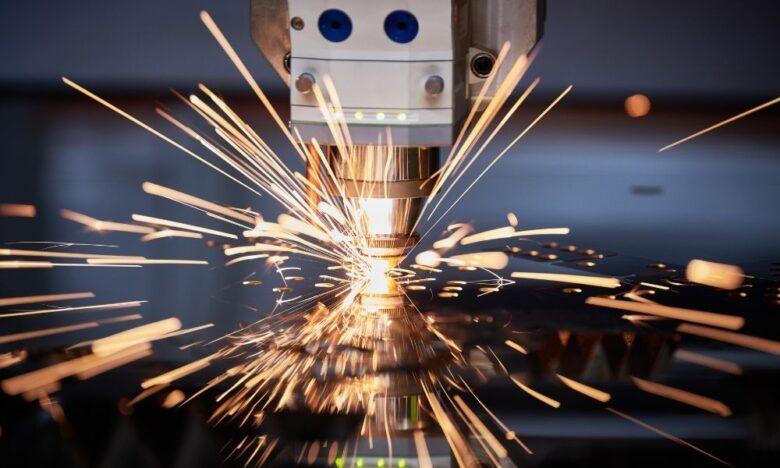

What is Laser Marking?

Source: rapiddirect.com

Laser marking is the process of using a laser to etch, engrave, or mark a material without physically contacting it. Instead, the beam creates a chemical or physical reaction on the surface of the material, leaving a permanent mark. The beam is highly focused and precise, allowing for intricate designs and small details to be marked with ease.

Automotive Industry

In the automotive industry, laser marking is a common practice to mark parts and components with identification codes, serial numbers, and logos for easy traceability and identification. This helps to ensure quality control and regulatory compliance, as well as to prevent counterfeiting and fraud in the industry. Additionally, this technology is used for barcoding and labeling, which plays a crucial role in the management of inventory and supply chain.

Aerospace Industry

Source: blog.ansi.org

This technology plays a pivotal role in the aerospace industry by providing an efficient means to identify and track various components. From identification codes and serial numbers to logos and barcodes, it facilitates traceability for quality control and regulatory compliance. In addition to its functional use, laser marking can also mark the location of drill holes or cutouts, making it an indispensable tool in aerospace manufacturing.

Medical Industry

This technology is widely utilized in the medical industry to ensure the accuracy and traceability of various medical instruments and devices. Specifically, surgical instruments are marked with identification codes and serial numbers to enable easy tracking, while medical devices like pacemakers and implants are marked with barcodes and traceability information for regulatory compliance. The precision and permanence of laser marking make it a reliable solution for the demanding requirements of the medical industry.

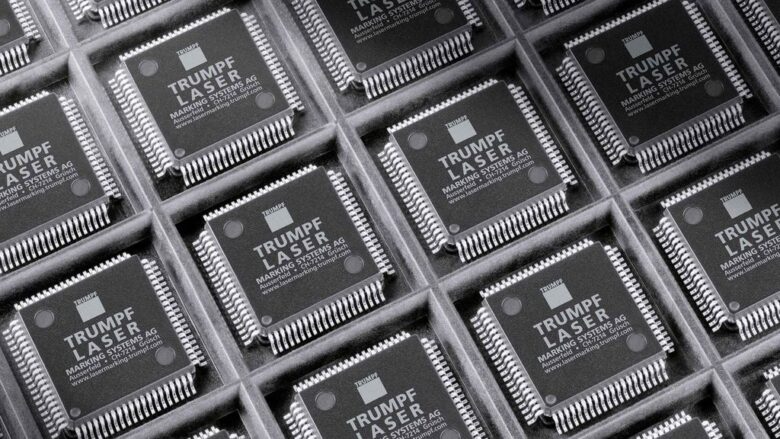

Electronics Industry

Source: trumpf.com

The electronics industry heavily relies on lasers for the precise and efficient marking of electronic components. The identification codes and serial numbers are marked on the components to allow for easy tracking, and barcoding and traceability ensure regulatory compliance and quality control.

It also serves a functional purpose in engraving the location of components on a printed circuit board, facilitating assembly and maintenance processes. With its ability to produce high-quality and permanent marks, laser marking is a crucial technology in the electronics industry.

Jewelry Industry

Laser marking has revolutionized the world of jewelry-making, allowing artisans to showcase their creativity and craft with stunning precision. From etching logos and trademarks to engraving heartfelt messages, this is a go-to technique for adding personalized touches to jewelry pieces.

With its versatility and ability to mark a wide range of materials, including precious metals and gemstones, this is an essential tool for elevating the aesthetics and value of jewelry. The jewelry industry has truly embraced the possibilities of laser marking, utilizing this technology to create unique and timeless pieces that leave a lasting impression.

Packaging Industry

Source: envion.fi

From barcodes and serial numbers to other identifying information, laser engraving ensures the traceability and quality control of packaged products. In addition to its functional uses, it can also mark the location of folds or cuts on packaging materials, improving the efficiency of the packaging process.

With its ability to create permanent and high-quality marks, laser marking has become a popular choice for companies seeking to enhance their packaging operations. The versatility and reliability of this technology have made it a critical component in the packaging industry, driving innovation and delivering better value to customers.

Firearms Industry

Laser marking is a game-changer in the firearms industry, providing a precise and permanent method to mark firearms with serial numbers, model numbers, and other essential identifying information. Beyond its functional use, laser marking allows for the customization of firearms, such as engraving a name or message on a firearm, making it a treasured and personal possession.

The versatility of laser marking technology enables firearms manufacturers to produce unique and intricate designs on a variety of materials, including metal, wood, and synthetic polymers, unleashing the creativity of firearm enthusiasts. As a result, it has become an integral part of the firearms industry, offering an efficient and reliable way to enhance the appearance and value of firearms while ensuring regulatory compliance.

When to Use Laser Marking Machines

Source: mac-tech.com

This technology has become the go-to choice for industries seeking precision, permanence, high production volume, material versatility, and safety in their marking processes. For the precision marking of intricate designs and small details, these machines offer unmatched accuracy.

Additionally, this technology produces a permanent mark that won’t fade or wear over time, making it ideal for long-term traceability and identification of components, such as in the automotive and aerospace industries. The ability to mark a large volume of parts quickly and accurately make marking machines an excellent choice for industries with high production volumes, like automotive and electronics.

Advantages of Laser Marking Machines

Laser marking machines offer a range of advantages that make them a top choice for businesses across various industries. Their precision is unmatched, allowing them to produce intricate designs and detailed markings with ease. With rapid and accurate marking capabilities, these machines are the ideal solution for high-volume production lines.

The versatility of laser marking machines enables them to mark a diverse range of materials, including metals, plastics, ceramics, and glass, providing businesses with the flexibility to handle a wide range of products. Furthermore, their non-contact marking process makes them safe and efficient, making them a popular choice for safety-conscious industries.

Finally, this technology produces a permanent and durable mark that doesn’t fade or wear over time, ensuring long-term traceability and identification of components. It’s no wonder that laser marking machines have become a crucial tool across numerous industries, offering businesses an unparalleled combination of precision, speed, versatility, safety, and durability.

Conclusion

Source: baba-blog.com

We hope this guide has helped you better understand what laser marking machines are and their various applications in different industries. With the continuous advances in technology, we can expect to see more industries utilizing laser marking machines for a variety of purposes – from automotive manufacturing to electronics production. As technologies continue to evolve, so too will our understanding and use of these powerful tools.