Let’s get started with our detailed solenoid valve 2024 guide, which includes thorough information about solenoid valves, their types, uses, how they function, and so on.

Contents

What Are Solenoid Valves?

To describe a solenoid valve, it is an electro-mechanical valve that is generally utilized to regulate the discharge of gas or liquid. So, it is used in several flow control applications to begin or halt the flow in the tube. As they are electromagnetically activated, it is possible to place these solenoid valves in remote areas. Besides that, it is easy to control them using convenient electrical buttons. In other words, a solenoid valve is an electrically regulated valve. The valve has a solenoid (an electric coil with a movable plunger) in the middle.

These solenoid valves can be utilized when it is necessary to automatically control the fluid flow (like in factory automation). The computer that operates the automation program can deliver a reminder to the solenoid valve to unlock, or shut down the solenoid valve. The gripper for clutching objects on a robot is often an air-regulated appliance. It is best to use one solenoid valve to close the electric gripper and another one to unlock it.

In fluidics, one of the most often used elements is solenoid control valves. These valves are generally necessary to close, discharge, dose, share or blend liquids. Due to these reasons, they can be seen in several application sectors. Besides that, solenoids are durable, compact, deliver quick and stable switching, feature low control power, and work for long periods.

Though there are different types of solenoid valves, the two primary variants are direct acting and pilot operated. It is alright to leave the flow meter as it is or incorporate it with the air brake or a liquid softener. If you would like to know more about different models of solenoid valves, make sure to check out chelic.com, where there are various styles, sizes, and collections of solenoid valves.

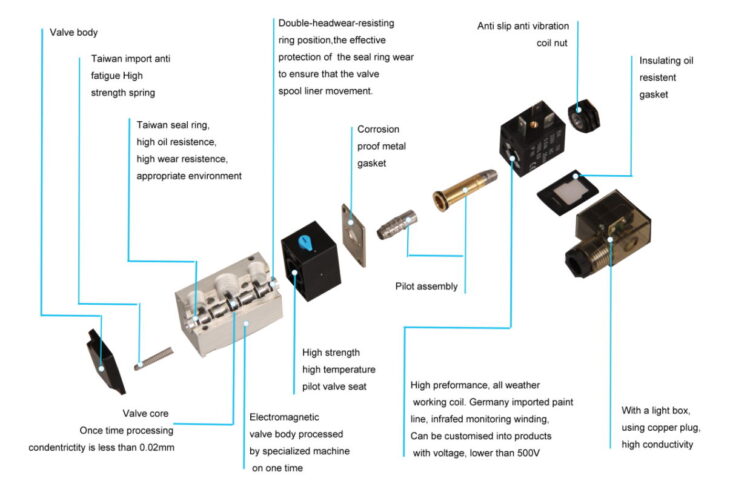

Source: xpneumatic.com

What Are Different Components Of The Solenoid Valve?

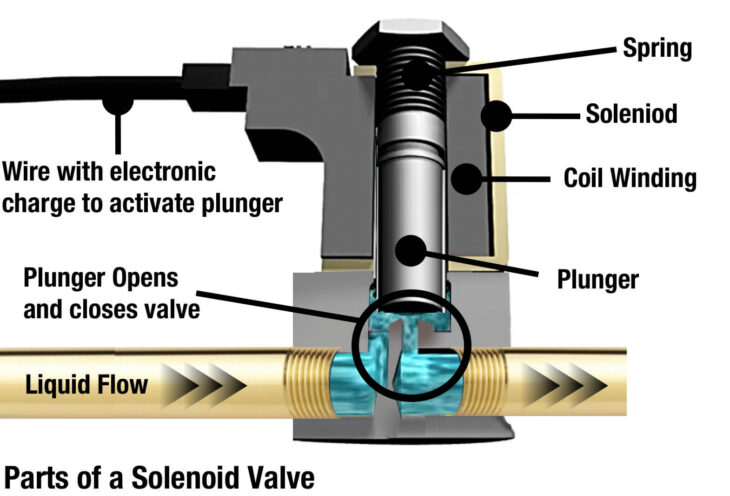

Generally, solenoid valves contain two fundamental parts: a solenoid and a valve.

The solenoid features various vital components, such as the coil, plunger, and sleeve assembly. However, the valve body is composed of multiple orifices (entrances). Here, we will see the detailed components of the solenoid valve:

Valve body

It is the valve’s body to which the solenoid valve is attached. In general, the valve is united in the flow pipeline to regulate the flow of specific liquids or gases.

Inlet port

Through this inner port, the liquids or gases will get inside the automatic valve. After that, the fluid can reach the final procedure.

Outlet port

The outlet port will discharge the fluid from the valve, which is enabled to depart through the automatic valve. The solenoid valve regulates the fluid’s flow from the inlet port to the outlet port. This outlet port is attached to the procedure where the liquid is necessary.

Coil or Solenoid

It is the solenoid coil’s body, which has a cylindrical structure. Generally, this body has a steel covering with a metallic finish, and it is empty from the inside. The solenoid coil is present inside the solenoid valve.

Coil windings

It contains several rolls of the coated wire wound all over the ferromagnetic substance such as iron or steel. This coil forms in a hollow cylindrical shape, and it has external steel covering. There is a plunger (piston) inside the open part.

Lead wires

These wires are the outside connections of the solenoid valve and are attached to the electrical supply. The lead wires transfer the current (power) to the solenoid valves. The current passes through lead wires when the solenoid valve is energized. If the solenoid valve is de-energized, the current flow will end.

Plunger or piston

The plunger is a durable and round metallic component, which has a cylindrical shape and is present in the hollow part of the solenoid valve. If the electrical current goes through the solenoid valve, the plunger will shift into a vertical posture in the open area. It happens due to the action of the magnetic field opposing the spring action.

Spring

Regardless of whatever the posture it is in, the spring will halt the movement of the plunger. The spring action is against the magnetic field, and it has a critical role inside the hollow space.

Orifice

Here comes one of the significant components of the valve. The orifice is a critical element because the liquids or gasses will flow through it. In addition to that, it acts as the connection between the outlet port and the inlet port.

Source: saferack.com

How Do Solenoid Valves Work?

Solenoid valves function by managing the progression of gases or liquids in a constructive, entirely closed, or totally open method. They are also utilized in place of physical valves or for monitoring via remote control. The purpose of the solenoid valve includes opening or shutting an entrance in the valve body to either enable or deter the flow via the valve.

Like we said previously, solenoid valves have plunger coil and sleeve assembly. The plunger will unlock or shut down the opening by going up or dropping off within the sleeve tube by stimulating that coil. In short, the solenoid valves function appropriately by utilizing the electromagnetic coil to unlock or lock the valve opening. If the coil, which is present within the solenoid is spurred, the plunger will go up or down to either open or shut the gap. It regulates the flow, which means controlling the movement of liquid or gas.

Normally Closed

When de-energized, this valve stays in the “closed” posture, which is one of the most ubiquitous operation techniques. In these closed valves, the plunger return spring will keep the plunger across the opening and curbs flow. After the solenoid coil is stimulated, the consequent magnetic field lifts the plunger, which allows the flow.

In general, these normally closed valves are utilized in On, Off, or venting operations, where there is a need to halt the process due to power loss. During the power loss incident, this valve shuts so that the liquid will not deplete.

Normally Open

When de-energized, this valve stays in the “open” posture. In the case of normally open valves, if the solenoid coil is spurred, the plunger shuts down the opening, which further deters the flow. The popular usages of these normally open valves are security applications where the procedure is unproductive during the power loss events.

Universal Valves

Universal valves are normally open or normally closed valves, which depends on the strategy the valve is joined in. This can be seen in 3- or 4-way valves where it is possible to impose pressure on any valve’s port.

Here are the most common valve problems to look out for:

The solenoid valve doesn’t open or close properly

The solenoid valve may fail to open or close properly due to various factors, such as insufficient power to the coil, a faulty coil, pressure differences, wrong voltage, or dirt accumulation in the valve tube or seat. The extent of the valve’s malfunction can also be influenced by its type, whether direct-acting or pilot-operated.

To troubleshoot the issue, follow these steps: first, check the power supply to ensure the voltage and frequency reaching the coil are within limits. Inspect the diaphragm for corrosion or dirt and verify that the coil is undamaged. Review the valve manual to confirm the flow direction matches the indicators on the valve body.

Ensure pressure levels meet specifications or adjust accordingly.

Melted or burnt coil

A burnt-out coil can result from factors like short circuits, under/overvoltage, damage to moving parts, or poor system cooling. Check the voltage specifications against the power source ratings, and look for any short circuits, fluid leaks, or excessive friction and high temperatures around the coil. Consider increasing ventilation around the valve if possible.

A persistent buzzing sound

Address a persistent buzzing sound, as it can lead to more significant valve issues over time. This sound may originate from loose or damaged mechanical components or alternating current noise. Try tightening loose parts, and if that doesn’t resolve the issue, consider using a rectifier unit in the valve circuitry to filter the noise effectively.

Final Word

At last, that is the end of our guide to solenoid valves. We included the up-to-date information, so it will be easy for you to understand solenoid valves, their types, functions, and other related things.