When creating a new product, you need to first create a prototype that will fully represent the design, as well as the item that we want to manufacture and sell. These units are used to help us understand what we are going to get, to see the design in a 3D model, and to notice and prevent mistakes that could cost us a lot in the long run, in case we don’t avoid them in this phase of the process.

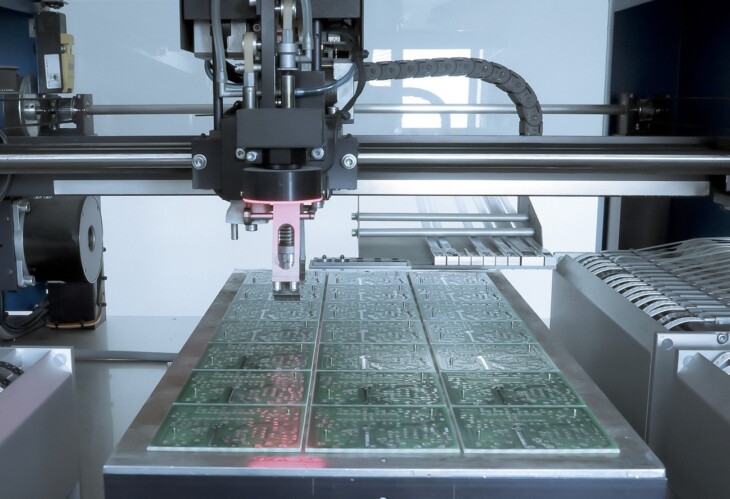

The printed circuit boards are the heart of every electronic device, and without them, the devices we have would not work. They support and connect the electronic components, and they are used in pretty much every industry in the world. In this article, we are going to give you more information about the PCB prototypes, and we will give you some tips that will help you with understanding the prototyping process.

Source: Medium

Contents

1. Choosing the right manufacturer

Before you start with anything else, you should know that the design and output are probably the most important things for the whole process, so you need to find the right manufacturer and designer for your specific needs.

You should look for places that take pride in their components, and that ensure the viability of the product. You also need to collaborate with a designer that knows how to reduce the risk of mistakes and rework. You should look for a place that will provide the best quality materials, along with budget-friendly fees.

2. Model parts

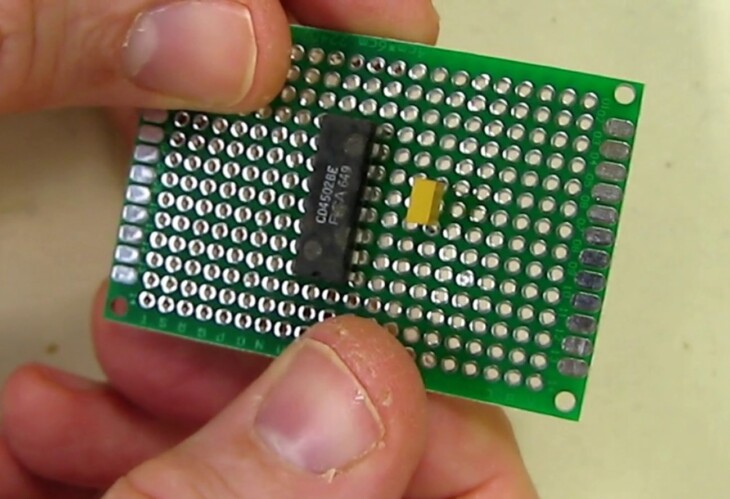

When it comes to design, the first thing you need to know is that there are several parts that consist of the model. They need to be made within the tools and they will represent the components that need to be installed on the mainboard.

In addition to this, they need to perfectly represent every single thing that the PCB is going to consist of, and they need to be created in a 3D print. This will help not only with the understanding process but also quality assessment and locating the errors.

Source: King PCB

3. Rules for designing the PCB

When you design a board, you need to follow a specific set of rules. These rules will help you with everything that comes with creating the mainboard.

Know that the list of these rules is really big, and you need to pay attention to every single thing. Some of these regulations include the size of the main object, as well as the spacing between the components.

Once you create the prototype, you need to use it for every future design. You should also pay attention to the location, pattern size, as well as trace routing.

4. Outline specifications

Another rule that you need to follow when you are creating the design for the prototype is the outline specifications. They need to be created using a special platform, including CAD, and you need to pay close attention to every single part of the outline.

Note that one of the most important things that the designs use the platforms for is creating the layers of the boards, deciding how many there are going to be, as well as the process of stacking and spacing them.

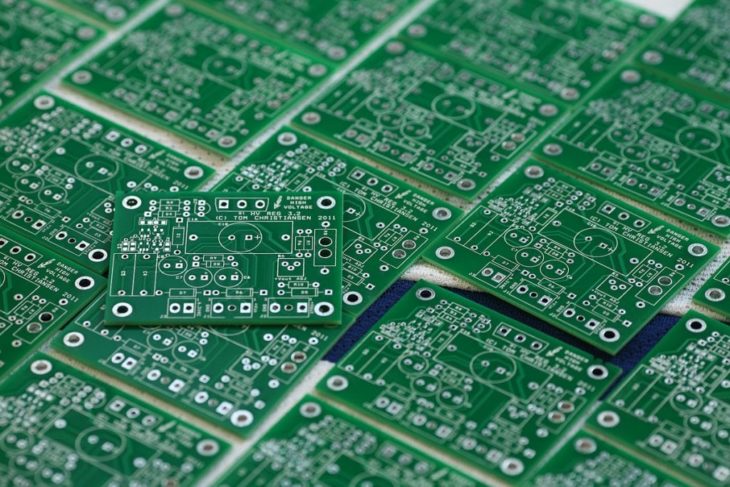

Source: ourpcbte.com

5. Learn the differences

There are two main types of printed circuit boards, and you need to know more about them and their differences before you choose the right type of model for you. They include the rigid and the flex printed circuit board.

The rigid type is far more used and more popular in manufacturing, but that does not mean that it is better for every product. This model is used on most of the traditional machines, as well as devices that we have in and around our household.

The flexible model is made with plastic-like materials, and it is commonly used in new types of technology including smart devices, keyboards, and some industrial devices.

As you can see on websites like uetpcb.com, when choosing the right model for you, you need to pay close attention to the manufacturer, as well as the materials used in the creation process if you want to get the best product or prototype for you.

6. Learn the pros and cons

You also need to consider the positive and negative sides of the two main models that you can create the prototype for. You should know that when it comes to durability, the flexible models are better for extreme conditions, whereas the rigid ones are far more durable in normal circumstances.

The cost for creating the rigid ones is usually lower when compared to the other model, however, this all depends on the manufacturer and specific materials that you want to use.

When it comes to more complex designs, and newer devices, users prefer the flex type, and when it comes to standard machines that need to be low-cost and really durable, they choose the traditional, rigid type.

Source: AMAC Technologies

7. Prioritizing

The last thing we are going to talk about is how to prioritize features when you think about layering the components. Note that as the boards are becoming smaller, the components are as well, but not everything can be downsized.

Because of this, you need to choose only the most important features that you can utilize in your items. When deciding on the things, you should talk to the manufacturer and the engineers, and let them know what they need to implement, and which functions are not as important. This will give them enough room to test things out, and to choose the best design depending on what you want and need.

These are the most important things that come with the production process of the prototype. Know that these are just some of the basic steps, and if you choose to create this model with all its components, you need to closely collaborate with the right manufacturer that will provide the best quality, along with the best prices. Consider all of your options, think about all the features and functions you want, choose the right materials and models for your product, and if needed, collaborate with an electrical engineer that will help you make all of the choices.