Energy consumption is a big problem because it increases the carbon footprint, so industries are actively looking for a solution that will at least minimize that.

As the energy prices are rising on a global scale, there is a short term necessity to reduce fuel bills to remain competitive on the market. This is where waste head recovery comes into play.

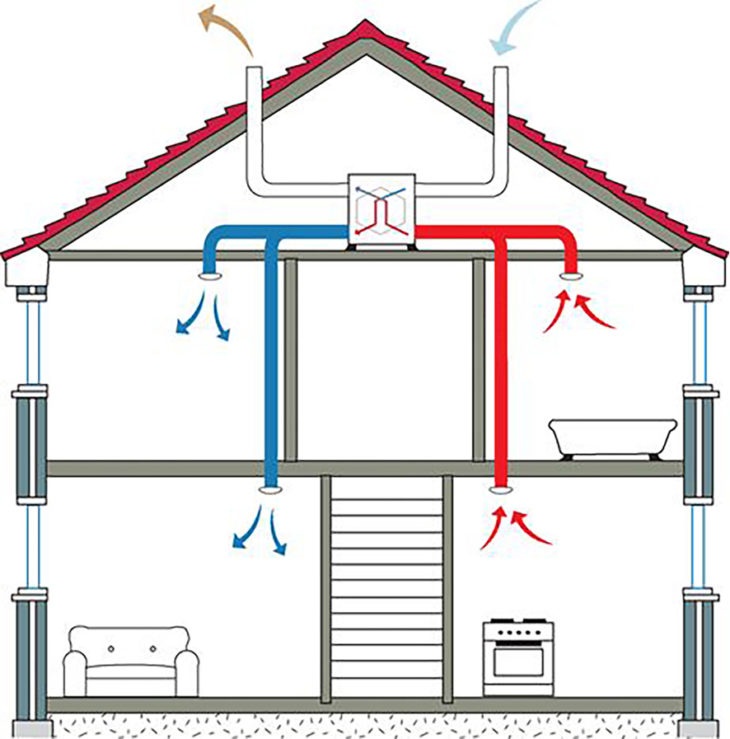

Source: BPC Ventilation

Waste heat recovery is a type of recovery system that has huge potentials in energy saving in existing systems. The logic behind these systems is that if we can reduce the fuel used to produce heat in boiler installation, we increase the efficiency of heating. This ultimately results in lowering fuel usage. CO2 emissions into our atmosphere have damaged the ozone layer and are severely impacting our climate. Global warming is a real thing that must be managed otherwise the situation will become so bad that it might become irreversible. A respected scientific journal, the Climate Dynamics”, published a report in 2016 and that report stated that some developing countries might have to reverse carbon emission at least by 2030 and some by 2050 if we want to put an end to this life-threatening problem.

And this is where waste heat recovery systems play their part. Not only do they increase energy efficiency, but they also reduce carbon emission and the carbon footprint.

The boiler, although humble in its own creation, is a huge energy consumer in many homes, factories, and other businesses that generate waste heat from the spent gases used to heat water.

If you’re looking into waste heat recovery systems, make sure to visit this website.

Source: Business Matters

What are the sources of waste heat?

The biggest sources for generating waste heat are boilers, furnaces, heaters, kilns, combustion turbines, engines, etc. A lot of waste heat is also produced from the food production industry, the juice production industry, dairy industry, breweries and distilleries, the coffee making industry, the heat treatment industry, can manufacturing industry, paper mills, automotive industry, metal industry, and industrial painting.

All of these types of businesses and industries are generating waste heat, and one way to cross them off the list of generators of C02 emissions would be to employ waste heat recovery systems.

Benefits for Choosing a Waste Heat Recovery System

Waste Heat Recovery Systems turn fuel gasses, steam, or hot process air into hot water. That’s the basis for reusing wasted energy that will save you money, reduce the CO2 emission in our atmosphere, and help the environment.

Waste heat recovery systems can be used in multiple ways such as for cleaning purposes, air conditioning and air heating systems, for bathing, absorption chillers, heating for your home, office, and production facilities, in the food and beverage industry, and more.

There are also benefits that come with using these systems such as:

- Quick return of investment: These waste heat recovery systems are predicted to be able to save you enough money that you will completely pay off the system in between 18 months and 24 months.

- Waste heat recovery systems are subsidized in most countries.

- Easy maintenance due to removable heat exchangers.

- Excellent for the environment, for decreasing CO2 emissions, etc.