As laser technology becomes better, faster, more efficient, and affordable, people can now buy these cutter and engraver machines for just a fraction of what the cost used to be. An average laser cutter 10 years ago probably cost around $10,000 or maybe even more. Today, you could get the same type of cutter for 1/10 of the price. For $1000, you could get a pretty good machine nowadays. If that is too expensive for you, there are even cheaper options at around $500.

However, with the growth of this industry and market, a lot of new brands and models have started showing up. Right now, Amazon, eBay, or any other online store is filled with these types of products. All of them promise different kinds of features, laser power, and who knows what else. But, are all of these products really that good?

Well, I do not think so. It is still not that simple to create a proper laser cutter. Some of these brands are just trying to make as much profit as possible by using cheap materials or cheap lenses. To avoid spending your hard-earned money aimlessly on a machine that does not provide you with what has been promised, I suggest that you first do a bit of research to find out what you actually need and which products are reliable and good.

To help you with your search, I decided to write this article and provide you with several tips for buying laser cutter and engraver machines.

Contents

1. Figure out your budget

img source: searchengineland.com

One of the first things you will have to figure out when going shopping for an engraver is your budget. Without confirming your budget, you will not be able to take the next step. Course, if you do not feel the need for a budget, if you plan on spending as much as you can on this kind of device, you probably should not worry too much about the machine that you will be purchasing. I assume that every product above $10,000 or more will be of very high quality. While purchasing from brands that produce models that cost under $1000, you will need to be more careful.

So, just exactly how much money you are ready to spend? In other words, how important is this machine for you? Do want to buy it just for fun, to experiment, or do you want to make a serious profit out of it? Do you plan to use it in your business or for personal needs?

Obviously, if we are talking about buying a laser cutter for helping with your business, you will need to expand a little bit more on your budget. Because a higher quality machine will provide you with the technology to cut easier, engrave an edge on all kinds of materials. You should build more about technologies that today’s laser cutters are equipped with to help you understand just exactly what you need.

However, if you are making this purchase for personal needs, you can cut down on the cost.

2. Consider the software

img source: amazon.com

Usually, these machines come equipped with a small screen and an operating system, software that allows you to run different kinds of programs on different materials. This is what allows you to input the types of engravings or cuts you want to make.

However, different brands use different types of software. Unfortunately, some of these brands have not exactly invested a lot of time or money into making properly optimized software. So, even if the device is great by itself, you can still be limited by the software that comes with it.

This is one of the reasons why I believe it is so important to consider the software when buying the hardware.

I believe that the best option is to just look at devices that are ready to work with third-party software such as Adobe or CAD. These are some of the most popular software is used for cutting or engraving. All you have to do is just plug in your newly purchased device into your computer and then you can do everything externally instead of relying on the software and the buttons of the device itself.

3. What kind of materials do you want to cut?

img source: walmartimages.com

Another very important thing that you will have to ask yourself before you make a purchase is: What kind of materials I am going to cut once I buy a laser cutter?

It is crucial that you ask yourself this question because not every machine is made equal. Some are made to cut or engraving to lighter or more fragile materials such as plastic while others are made to cut things such as aluminum or maybe even steel. The difference in power between these two machines is huge. If you try to cut with a very powerful laser into plastic, you will not get a good result, trust me. You can read more about boss lasers, for instance, and see what kind of laser that is.

Although, most modern devices today usually have an option to lower the power of the laser or increase it. But, even that option is limited to a certain amount.

If you plan on cutting into different metals, make sure that the laser will be powerful enough to do that.

4. Size compatibility

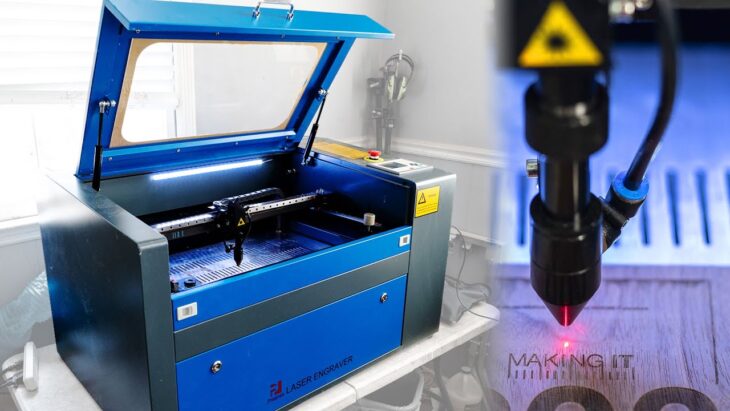

img source: ytimg.com

I assume that you are buying this type of device because you already have a plan on what want to cut or engrave. Otherwise, you would not be here reading this article. Well, if you do have in mind what kind of objects you will be working on, you will have to consider the size compatibility of the laser machine.

Every laser cutter has a certain amount of workspace. Cheaper products usually have a smaller workspace that is somewhere between 100 mm and 500 mm. That does not sound like a lot, but it is great for smaller objects such as keychains, cups, or whatever else you can think of. The more expensive ones for a larger workspace.

As you can see, there are a couple of things that you will definitely have to consider before making a purchase. I hope that this article has provided you with the information that you needed.