The liquid flow measurement’s use is very crucial to many different industries, including, wastewater treatment industries, water industries, oil, and power industries. These different industries need to determine or learn the exact amount of liquid flowing through a pipe. A liquid flow meter is used to know the volume of liquid passing through a flow tube so that you will know your bill or how many bulks of products you should produce. These are instruments or devices used to measure the non-linear, linear, volumetric, or mass rate of a fluid.

It’s leveraged in many applications, for example, tanks, chambers, pipelines, natural sources, usable industry chambers, and many more. Liquid flow meters are available with many mechanisms and features. For a little help, here are the different types of liquid flow meters. So, take a read!

Contents

Types of Liquid Flow Meters

Source: Vortex flow meter

There are various types of liquid flow meters based on the material, nature of applications, construction, and the particular liquid. Listed below are the basic categories of the liquid measuring devices.

Velocity Flow Meters

Velocity flow meters function directly with the flow rate’s volume. It converts the data of the water’s velocity into its volume. If the measuring device is utilized with Reynolds number at least ten thousand, the velocity flow meter becomes susceptible to the fluid’s viscosity change. Velocity flow meters can be divided into vortex flow meters, Calorimetric, Turbine, Electromagnetic, Pilot Tubes, Swirl, and Ultrasonic Doppler.

Differential Pressure Flow Meters

Differential Pressure flow meters are the most common and generally known measuring devices in use. It consists of a primary and secondary component. The first one converts the kinetic energy, while the second component measures the differential pressure, producing a signal that can be altered to calculate the flow rate.

DP flow meters can be divided into Rotameter, Flow Nozzle, Flow Tube, Orifice Plate, and Venturi Tube. Differential Pressure flow meters measure or calculate the differential pressure through an orifice wherein the fluid is in proportion to the produced differential pressure’s square root.

The generally known use of a DP flow meter is within the gas and oil industries. Also, it can be applied in beverage, paper, pharmaceutical, chemical, water, HVAC, and mining industries.

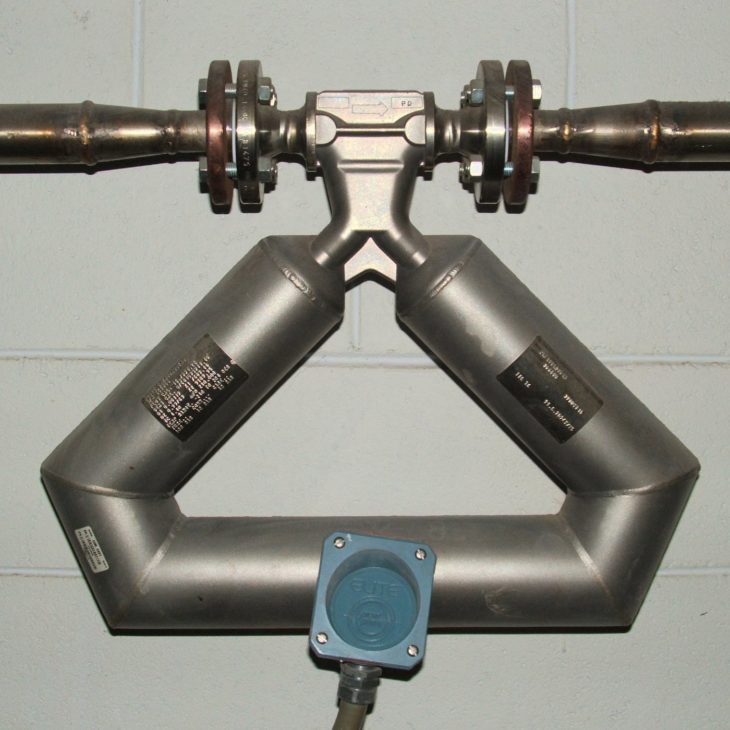

Mass Flow Meters

Source: Wikipedia

Mass flow meters calculate or gauges the mass of liquid passing through a pipe per unit of time. This measuring device can be divided into Thermal and Coriolis flow meters. So, when dealing with mass-related processes, these are the best, ideal, and most effective tools as they measure the force that’s generated by the speed of the mass. The typical applications for these include wastewater, pharmaceuticals, power, mining, gas, and chemical industries.

Positive Displacement Flow Meters

This flow meter type measures the chamber loaded with liquid, carry it further, and fill it up again. In this way, the flow meter itself gauges the quantity of fluid being carried from here to there.

According to smartmeasurement.com, in comparison to all other liquid flow meter types, positive displacement models measure the actual flow of any fluid, while other liquid flow meters measure a different parameter and translate the results into flow rate. The liquid’s flow is measured by how many times the chamber is loaded and emptied.

PD flow meters can be divided into Nutating Disc, Rotary Vane Meter, Reciprocating Piston Meter, and Oval Gear. Moreover, these are well-known for their accuracy. They’re generally or usually used in the transfer of hydraulic fluids, gasoline, and oils.

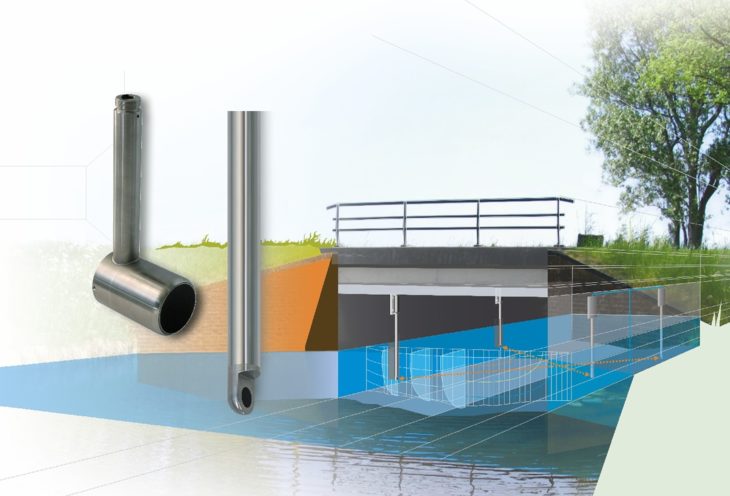

Open Channel Flow Meters

Source: NIVUS GmbH

Open channel flow meters refers to the fluid moving in the open surface and determining the amount by calculating the water depth. Flumes and Weirs are the two classifications of open channel flow meters.

These structures or overflows are like dams, storing a concentrated or restricted free flow of the fluid based on the shape and size of the structure. These need a level measurement aside from the velocity. The empirical equation is then utilized to measure the true flow. The common use of units like this includes free-flowing liquids, for example, wastewater systems, streams, irrigation channels, and rivers.

Closed Pipe Flow Meters

This type of liquid flow meter is used for liquids traversing in a closed chamber such as fuel pipeline, water pipeline, kitchen pipeline, sewer, and whatnot. Closed pipe flow meters are installed near the pipes to obtain the exact result. And the results are displayed or presented on the meters affixed or mounted to the conduits.

Takeaway

For most industries, liquid flow measurement is crucial and vital as these industries need to get the exact amount of liquid moving or traversing through a point. There are different types available in the market nowadays. These are velocity, DP, PD, mass, open channel, and closed pipe flow meters.