Technology doesn’t seem to stop progressing and evolving, and every other day we’re introduced to something brand-new and revolutionizing. Less than five decades ago, computers were as large as an entire house, and they couldn’t do more than completing a simple math task.

Today, we have thousands of times more powerful systems in the form of a smartphone, a device that can fit right into our pocket, and we’re still not even close to finished. We cannot tell where all this technological progress will take us in the future, but we hope that we’re headed in the right direction.

The reason why we’re able to have such small yet powerful devices is due to the constant advancement in the Circuit Board Production Field. As we all know already, circuit boards are the main component of so many electrical devices that we use daily, including our smartphones.

But now that we already have those, what’s the next step? – You’re probably wondering. Well, the answer is so simple but shouldn’t surprise you at all. Welcome to an article in which we’ll talk about the five main advantages of using a flexible circuit board, or a flexible PCB for those of you who want to use the shorter name for it. We’ll make sure to explain everything as we go, and since it’s a pretty interesting subject, let’s end the intro right here and jump straight into the content.

Contents

1. Can fit in much smaller designs

Source: EDN

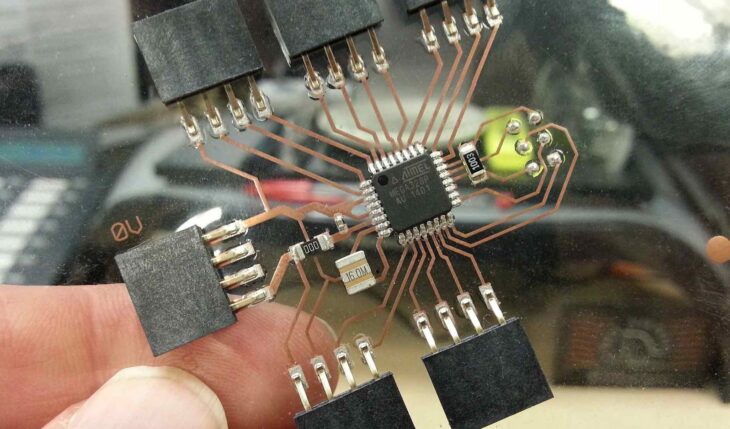

We already mentioned above that the devices these days are becoming relatively smaller compared to what we had in the past. If you’ve ever wondered why, well, it’s because this allows us to carry our mini-computers with us wherever we go, making our lives easier. Smart-watches, alarms, cameras, and sensors are all much smaller compared to what they were in the past. With the introduction of flexible PCB’s, designs can get a lot more creative and probably even smaller as well shortly. The ability to bend the circuit board will allow inventors to have more freedom when designing products.

2. Allows for much more opportunities

Source: Medium

Not only that, we’ll get smaller, more convenient products, but the designs can become a lot more interesting as well. Flexible PCB’s offer a lot more opportunities to the inventors because of many reasons, one of the main ones being the size and the ability to bend, obviously, but also the fact that they won’t have to use connectors. If you happen to be interested in learning some more in-detail on this subject, feel free to check this out.

We wouldn’t have those sweet LED-light stripes that can be controlled via a remote if we didn’t have flexible printed circuit boards, which is one of the examples why they happen to be so important in the industry.

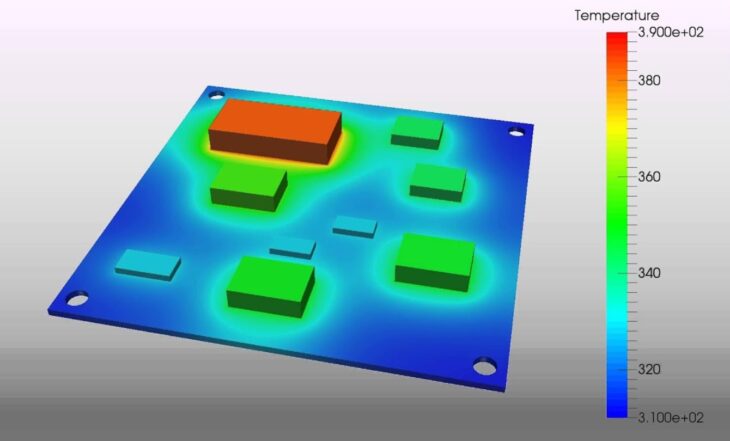

3. Much better thermals

Source: YouTube

If you’ve ever used any type of electronics in your life, the chances are that you’ve been introduced to the “heat factor” at least once before. We all know that leaving the blender or the laptop on for a very long time will cause it to overheat, and that’s when we start experiencing issues with our gadgets. Well, we’re more than happy to let you know that the flexible PCB’s have much better thermals than the regular ones. This will allow inventors to push the performance of all the new gadgets to the limit by allowing them to operate at a much higher power without worrying about the temperature. Also, you won’t have to worry too much about something burning on the circuit board, because these will be a lot more durable in that aspect.

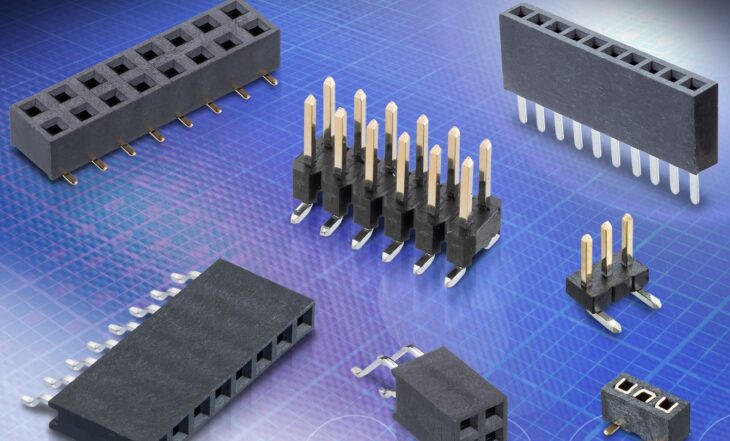

4. No more connectors

Source: Harwin

The ability to remove the need for connectors is truly amazing and makes things so much easier in a product that benefits from every millimeter of free space inside. If you were to use connectors for those complicated designs in which you need to fit multiple boards at once, you’re losing a lot of valuable space, and it’s simply not practical, according to some of the most successful manufacturers.

We all want our smartphones to be lighter, our laptops to be smaller and the overall design of our gadgets to be much fancier as time goes by. Well, this is more than possible with the utilization of the flexible printed circuit boards, the better thermals, and, most importantly, the no-need for connectors that increase weight and take up space.

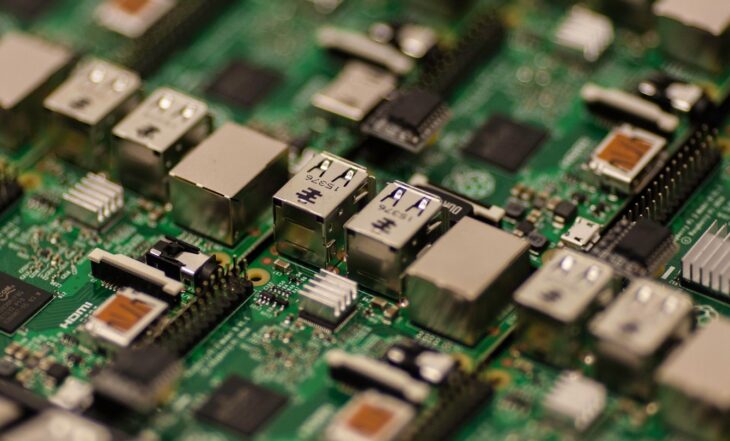

5. Can stack more into a device

Source: Medium

Last but not least, the main reason why flexible PCBs are considered more practical than the regular ones is that… well… they’re flexible. It’s simple but very true. To place multiple regular PCBs into a product, you’ll either have to modify the design and make it look not-so-slick, or you’ll have to deal with the fact that your product simply doesn’t look or feel very “futuristic” and fancy.

Thankfully, you can avoid all of that by using flexible printed circuit boards and stack them in many different ways due to their very practical ability to bend in multiple ways. As we mentioned in our example from above, imagine having LED-stripes that don’t bend, and you have to attach them as sticks on your wall, completely limiting your ideas. Now nobody would really like that, right? It’s very cool how such a simple change can have so much impact.

Conclusion

It doesn’t seem like much, but the ability to bend a circuit board without risking any damage is a revolutionizing invention. This will for sure open up a lot more possibilities in the world of technology, and since it’s a relatively-new thing considered the rate of change and progression in this industry, we can expect some pretty amazing products because of it in the future. Above, you can find our top five reasons why this design is superior compared to the regular, rigid circuit boards. This still doesn’t change the fact that some designs and gadgets require the combination of both types of PCB’s to get the best out of both worlds in terms of performance.