High noise levels caused by machinery and heavy industrial equipment is something employees have to constantly deal with. To avoid causing harm to the worker‘s hearing, it is crucial to reduce noise levels in factories, construction sites, and other places. The best solution for the problem comes in the form of customized rubber suspension solutions, so here is everything you should know about the technology and in what industries it can be used.

What It Is?

These rubber suspension units, as the name suggests, are made out of rubber and they have three main functions. Firstly, they can serve as an anti-vibration mount, the units can also act as a torsional spring, and can be a pivot bearing.

Oscillating mountings are especially useful for manufacturers of vibrating conveyors and screens. No matter if it is a free oscillating conveyor, a guided shaker one, or a gyratory sifter, these solutions are designed to fit many systems.

Anti-vibration mounts are perfect for canceling out any types of vibrations and there is a wide range of these solutions you can choose from. Companies such as ROSTA AG offer ones that can absorb low and medium frequency vibrations, at the same time taking on compression, tension, shear loading, and even combined loading. It is guaranteed that these mounts will not tear off, and they will handle the job no matter if the absorption is active or passive. They are also easy to install and can be placed on ceilings and walls among other places.

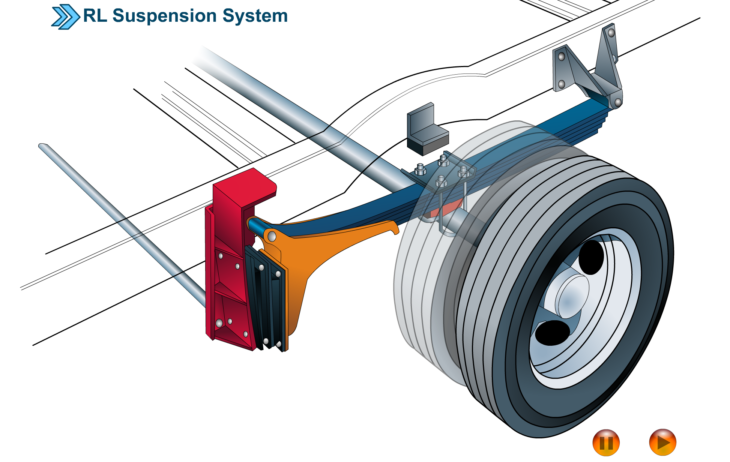

Source: truckinginfo

What Are the Benefits?

There are 124 standard modules to choose from and all of them offer numerous benefits. There is no need to maintain them, yet they have a long life. The units are completely noiseless and have no wear parts. They can also boost an entire system‘s performance while having an extremely low life cycle cost.

Where Can This Technology Be Applied?

Rubber suspension units have a limitless number of uses and applications. They can be used in industrial solutions for HVAC, vehicles, machines, snowplows, and large ventilation. In the mineral and mining industries, they can be utilized for rock crusher drives, vibrating feeders, screens, slurry pump support and more. In agriculture, they are useful for hay bailers, harvesters, shaker conveyors, tillage equipment, and other general farming equipment.

These units can be implemented in construction machinery and can also be used in wood processing. In construction, they might be useful for mobile crushers and screens, as well as chain and belt drives. In wood-processing, the technology can be used for transfer lines, chipper drives, shaker conveyors, and gyratory sifters.

They are also great for food processing solutions and can be used on different screens, sifters, and conveyors, as well as separation tables and freezing lines. Most interestingly they can be applied in seesaws, rocking toys, and other playground furniture, as well as outdoor fitness equipment.

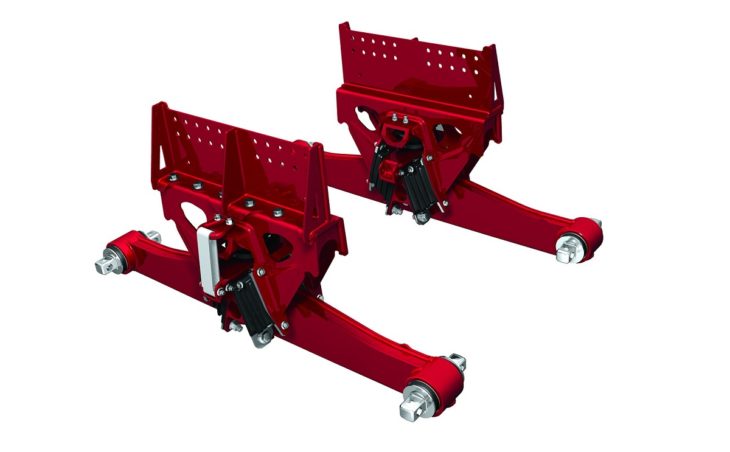

Source: morryde

Conclusion

Rubber suspension technology protects workers while providing other benefits to machines and companies as well. They are highly customizable units that are extremely effective in insulating noises, so you should consider implementing them in your equipment and machinery as soon as possible.