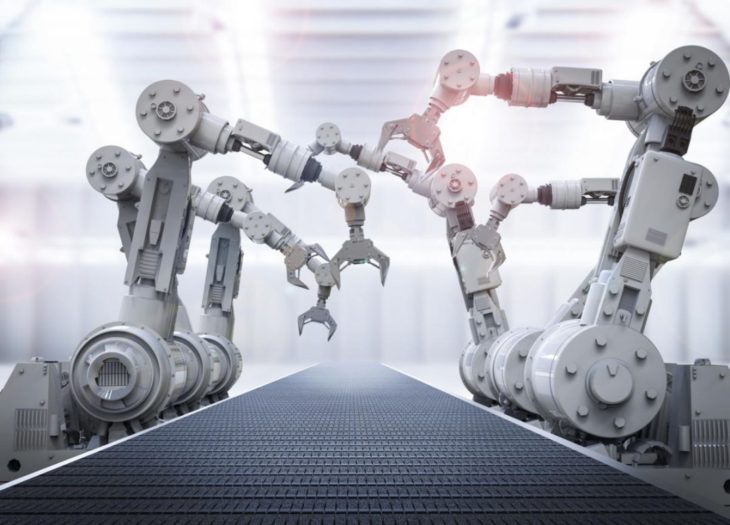

Ever since robotic instruments and machines were created, the main goal was to help us humans with some of the tasks that are too dangerous or complicated for doing on our own. Today we’re talking about robotic hands and how they are helping us on a daily basis in the automobile industry, so without any further ado, let’s take a look at what you need to know.

What are the robotic joints?

Robotic joints are basically the same types of joints that we have in our human arms, except they are made out of metal and controlled by a computer chip. They are movable parts that are able to adjust accordingly to the situation. Some tasks in the modern industries require us to do certain things that are pretty dangerous and expose us to a high risk of injury, so instead of doing them ourselves, we use robots that help us.

Source: theconversation

For a long time now the automotive industry is known for implementing a lot of robotic action in the processes of creating an actual car, and this started happening somewhere around 1960. Of course, the machines they used back then were nothing compared to the ones we have today, but so were the old cars compared to the modern-day ones.

A very common example is the robotic arms that were given “eyes”. Sure, a robotic arm is very useful when it comes to helping you reach an area that is either impossible or very dangerous to reach with a human hand, but that can’t really be possible if the arm cannot “see” for itself. In order to make this work, engineers started implementing cameras to the robotic arms, as well as a laser. With these two things combined, everyone working on that particular area of the car is able to give instant directions to the robot. If you are interested in learning some more, feel free to visit Rozum.

Some of the most popular car brands such as VW and Mercedes are using these robotic joints in order to make their designs as sophisticated as possible. If it were just humans working on these cars, they wouldn’t be as top-notch as they are at the moment. Unfortunately, some tasks are way too complicated for our bodies, but we are able to program machines to do them for us.

Source: marii

Now here comes the very interesting part. Humans are not even close to being excluded from the production of top-tier vehicles, so here’s what engineers came up with. Robotic hands that are used in the automotive industry are allowing workers to greatly reduce the stress on their real hands and give them a gripping strength of nearly five kilograms. This might sound a bit “clunky” at the beginning, but when you actually see how these things work, you’ll understand that they are pretty sophisticated after all. These exoskeleton devices come with tons of sensors and simulated nerves, and you are able to do all sorts of things with them after learning how they work.