You have an awesome idea to advertise your new business with enamel pins. But how complicated is this process and is it any effective? A lot of people think that making your own enamel pins is a very complicated and long process. It is not at all. It is actually pretty straightforward and easy and it probably will not take more than 2 or 4 weeks.

So if you are asking yourself how to make these enamel pins be successful then make sure to follow our guide with steps on how to get the right enamel pins for your business or event.

Contents

Prepare your design

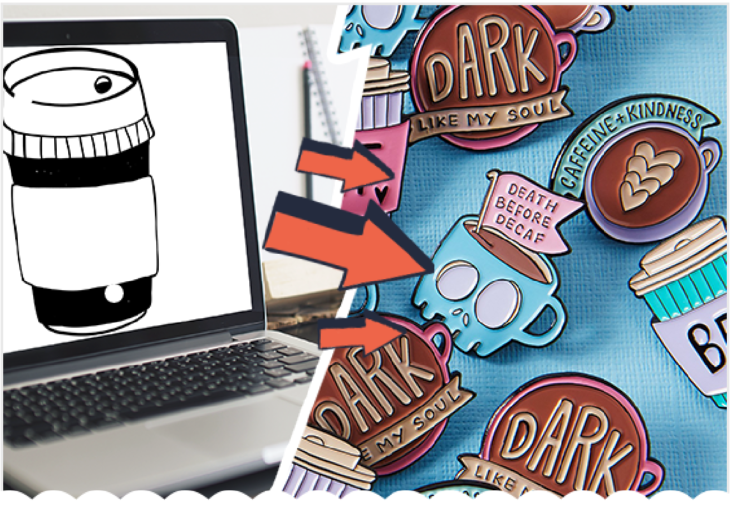

To start production of an enamel pin, most pin factories will ask you for a PDF file of the design you want to get produced.

If you know how to use graphic design software then you can send them a project file of your design that you want to be made into a pin. If you are not graphic design savvy then you can draw and color a quick sketch to get a general idea of what you want on your pin.

We can give you a few design-wise tips that could make your enamel pin process easier.

Source: All About Pins

Design tips

Enamel pins are very small in size which means that the surface area for a print is also very small. Having fewer details and lines is a much better option to print it on your enamel pin. If you have a very high quality and well-designed artwork could be an issue for the manufacturing process and even come out as worse than one with a simpler design.

Use bright colors and bold lines to make your enamel pins stand that when compared with others’ pins.

Colors on an enamel pin are very limited which is why you need to focus on the details and lines and forget about shading your design. Save yourself and the factory’s time and avoid asking about shading on your pin.

Decide what material you will use for your enamel pin

Enamel pins can be made from a huge variety of materials. However, there are two very famous pin styles that most people stick to. Soft Enamel and Hard Enamel pins. Keep reading if you want to read the difference between these two.

If you are looking to create and sell your custom enamel pins then we recommend you check out EnamelPins.com for a great offer.

Source: The Lily

Hard enamel pins

The defining characteristic of these hard enamel pins is the feeling of sturdy quality with precise thin metal lines for each color. They also feel very smooth with a hard enamel finish. They are usually made from die-struck iron and produced by heating the metal to a high temperature and finally polishing and creating the smooth surface which gives them the durable and quality feel.

Soft enamel pins

The most important characteristic of these kinds of pins is that they have the ability to have much more detailed prints at a much lower cost. They are also made from die-struck iron metal, but then they are electroplated with epoxy coating on top which gives them a thinner feels when compared to Hard Enamel pins.

Source: Creative Boom

If you want to make the perfect enamel pins for your business or simply for yourself then make sure you follow our guide with our tips to get the best result.