Highly-developed technology has changed our lives. Today, we can detect even the smallest failures in mass production. Modern technology has enabled us to achieve this with the help of special machines. Such machines will detect every, and even the slightest mistake.

This applies especially to the automotive industry, military, print&packaging and the food industry.

Contents

Brief History Of Visual Inspection

In the 1950s, image processing became a testing project for the machine industry. Visual inspection was born as a mechanism for testing production. During the 60s and 70s, the rocket and space industries began to evolve. Manual production detection could not meet such a challenge. Simply, such technology couldn’t thoroughly test missiles and other precision industrial products.

Therefore, visual detection machines began to emerge. In the 1980s, the mechanical vision was applied to the semiconductor industry, which was developing in an upward direction. During the 90s, the advent of intelligent cameras enabled the rapid development of visual inspection technology. That promoted the visual application in the manufacturing industry.

Source: Radiant Vision Systems

The Industry Must Keep Pace With New Technologies

With the invention and popularization of digital cameras, old cameras were eliminated, and the cost of the visual inspection was greatly reduced. In 2005, the world’s first visual inspection machine with a human-computer interface was launched. Since then, workers operate visual inspection equipment on the production line much easier. Today, the European Union, the United States and other countries have made regulations connected to visual inspection.

These countries specified standards that product manufacturers must comply with. Therefore, the use of visual inspection machines became inevitable. Several manufacturers have designed highly intelligent visual detection solutions. Many companies have begun to understand the importance of using these machines. They started to install a visual inspection system on their product lines. In short, the technology and mechanism of visual inspection are widely promoted.

Improvement Within This Industry

During the process of inspecting products in manufacturing facilities, people recognized a need for more improved machines. The ones that will have stronger sensors. The ones that can go beyond the current capabilities. With the development of new technology, this has become feasible. You might think that such machines are expensive and inaccessible to most manufacturers on the market. But it is not so. They can also be affordable and equally easy to install and adjust.

Today, many respectable companies in the industry offer “user-friendly” visual inspection products. According to Sipotek.net, such solutions are designed so that all adjustments can be made by operators on the production line. Also, modern embedded sensors can cover many different product formats on a single line. That way, each format is being stored in the sensor memory and recalled from it when needed.

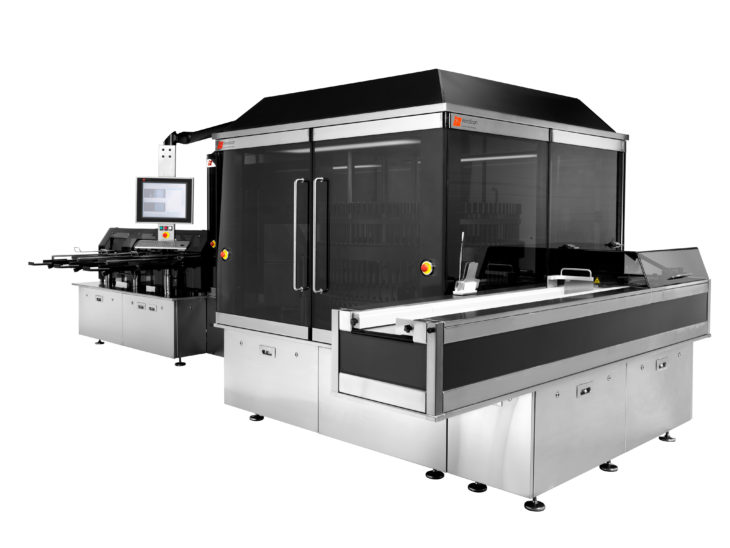

Source: Stevanato Group

Industries Covered

These smart machines have widespread use in many industries. The production covered by these machines is of great importance. It includes industries such as the manufacturing of military tools, automotive parts, pharmaceutical manufacturing, printing, precision hardware, electronics, plastics, etc.

Since it is used in many significant industry sectors, a visual inspection system must be following the latest technology improvements. Therefore it embodies sensible cameras, extremely sensitive sensors, machine and compact vision cameras, lighting, frame-takers, strong lenses, etc.

Serious manufacturers always strive for quality. Therefore the use of visual inspection machines has found its wide application. These machines are capable to thoroughly control your goods and products and to respond to the needs of high standards applicable to particular industries.